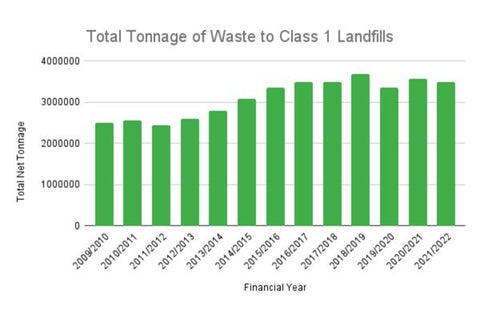

We have a waste problem in New Zealand. Yearly, we create 17.49 million tonnes of waste with 12.59 million tonnes going to landfill (76%). Adding to this problem is a low recycling rate. We only recycle and compost around ⅓ of the materials we place out on the curbside and ⅔ is sent to landfills (Ministry for the Environment). In contrast, countries like Germany recycle ⅔ of all waste and send to landfill just ⅓ (Radio New Zealand)

Waste causes harm to the environment and community, with pollution being a common output. Some of the most common instances are:

- Soil Pollution: Waste can leak hazardous material into the soil, making its way into our food

- Air Pollution: The burning of waste at landfills releases toxic substances into the air (such as the extremely poisonous dioxin)

- Ocean Pollution: Every year, 13 million tonnes of plastic lands in the world’s oceans. Keeping this trend going, by 2050 there will be more plastic than fish

- Groundwater Pollution: 280 billion tons of groundwater is being polluted every year - that’s 9000 tons per second!

As a country, we clearly need to reduce our waste creation. But what is waste, exactly?

Waste is something that is thrown away because it is no longer useful in its current context. Depending on the product life cycle, waste can be created at different stages. At the start of the cycle, materials can be a by-product of production processes. An example of this is fly ash from a furnace. Later down the product lifecycle, waste may result from the inherent value being lost. This may be a newspaper being read, a package that’s been opened and emptied, or an apple that’s eaten to its core.

One of the most common product lifecycles is called “cradle to grave”. This process has 5 key steps (Ecochain):

For creating clay bricks, this is what the cradle-to-grave process looks like:

- Raw material extraction: Clay is extracted

- Manufacturing and processing: The clay is added to brick moulds and fired

- Transportation: The finished clay bricks are transported to a project’s location

- Usage and retail: The bricks are then used to build a structure

- Waste disposal: Once the structure is no longer useful, it’s demolished with the bricks being disposed of

To effectively transform how waste is treated in New Zealand, we need to stop using the cradle-to-grave model. For a more sustainable future, we need to avoid waste being produced and added to landfills.

We’ve made it our mission to reduce concrete waste - it’s why we exist.

For the last 18 years, we’ve been perfecting a circular economy approach that reuses high quality, certified excess ready-mix concrete. This excess concrete is perfectly usable concrete, it just simply is no longer useful in its current context (i.e. left over at the end of a concrete pour)

Concrete waste is a significant issue as our modern world is literally built on it. In New Zealand we produce over 10 millions tonnes per year. About 300,000 tonnes - or seven sky towers worth - of this high quality, certified, concrete will end up as waste, simply because it can not be used before it sets.

We work with NZ’s leading concrete companies to close the loop on concrete waste for good.

Success requires capturing excess concrete in a usable form, and creating products that can be mass produced and mass marketed, without any reduction in quality. Matching seemingly unpredictable supply with mass market demand is our core competency.

We do this through our Interbloc and Stonebloc precast wall systems. At the core of the systems are proprietary block designs. The block designs look simple enough, but when you dive deeper they deliver a powerful combination of benefits.

(Interbloc concrete blocks used for the Waterview Tunnel on the left and Stonebloc used for a home in Pokeno)

They start life with ultra low embodied carbon, and continue to reabsorb carbon over their life.

They reduce time, labour, and materials waste during installation.

They deliver unparalleled durability, increasing the life of the structure.

They can be non-destructively dismantled and reused at the end of life.

We’re calling this approach the CarbonSmart® - Low Carbon, Zero Waste sustainability system.

Envirocon’s CarbonSmart system delivers a comprehensive circular economy solution for all asset owners, developers, civil, and construction companies.

- Scale: Envirocon operates 36,000 tonnes of capacity per year and is growing that at a rate of 420t per week.

- National Footprint: Our network has 4 sites across New Zealand, and we’re opening three sites a year for the next few years.

- Orthodox Engineering: Our construction systems are backed by orthodox engineering principles and are fully compliant with all NZ codes.

- Easy Sustainability: Envirocon’s systems are deliberately designed for simple sustainability - To achieve the changes New Zealand needs, it has to be easy

- High Productivity Construction: Interbloc and Stonebloc are designed as low labour, high speed construction systems to help boost productivity in our construction sector.

- Non-Destructive Dismantling: Interbloc and Stonebloc structures can be non-destructively dismantled.

- Endless Reuse, and Unique Buyback Guarantee: Our blocks can be endlessly reused, and we offer a unique buyback guarantee on Interbloc so when you no longer need them, we’ll take them back.

By choosing Interbloc or Stonebloc for your project, you’re actively participating in transforming New Zealand into a circular economy.