STONEBLOC HELPS YOU MAXIMISE YOUR LAND WITH TIMELESS RETAINING. HOW DO WE DO THIS?

GREAT DESIGN.

Stonebloc is a precast concrete retaining wall system that combines fast installation with unmatched durability. Its unique stonemasonry design creates a timeless aesthetic that complements any setting. Built to last for decades, Stonebloc is a solution that stands strong for generations. With minimal foundation needs and an efficient build process, it delivers both style and practicality.

Benefits of STONEBLOC

Product Information

Stonebloc BrochureTechnical Information

Case Studies

Get In Touch

Contact Us0800 468 375Stonebloc is best used for

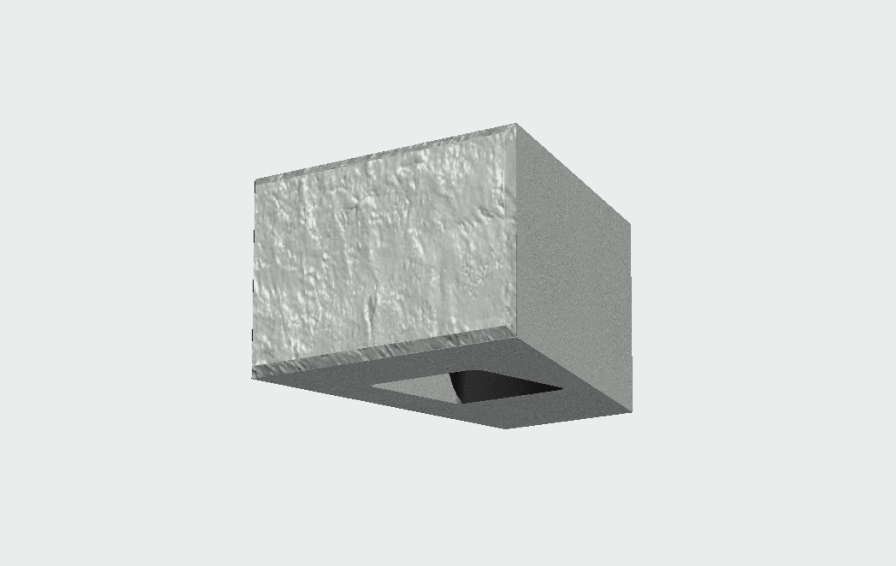

A STANDARD STONEBLOC

OFFERS A RANGE OF DESIGNS FOR WALLS UP TO 2M HIGH

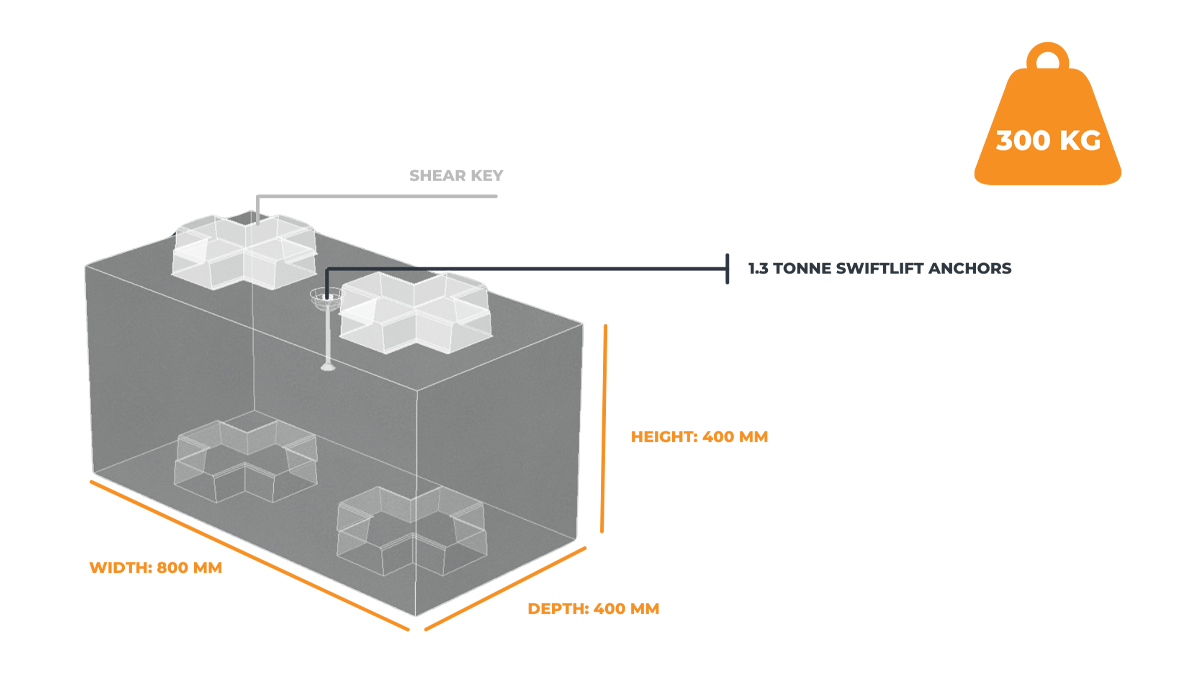

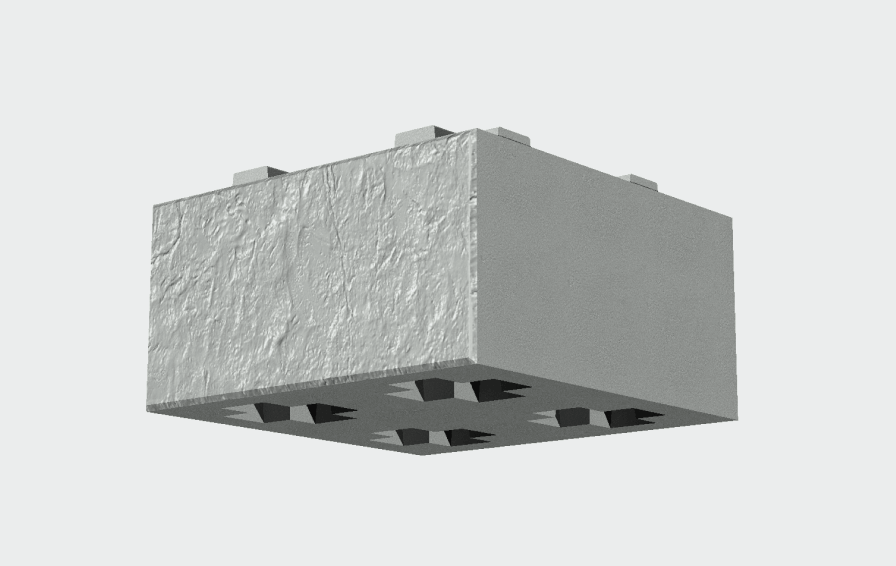

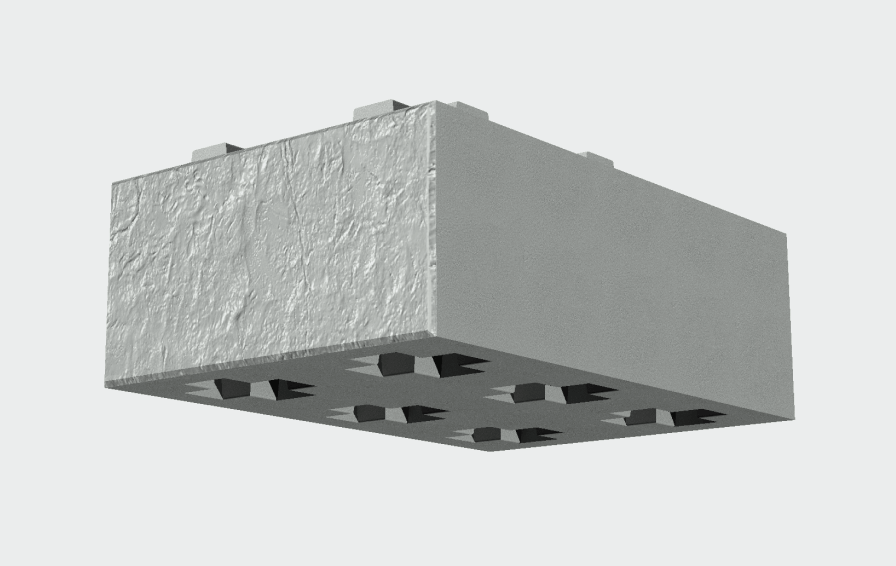

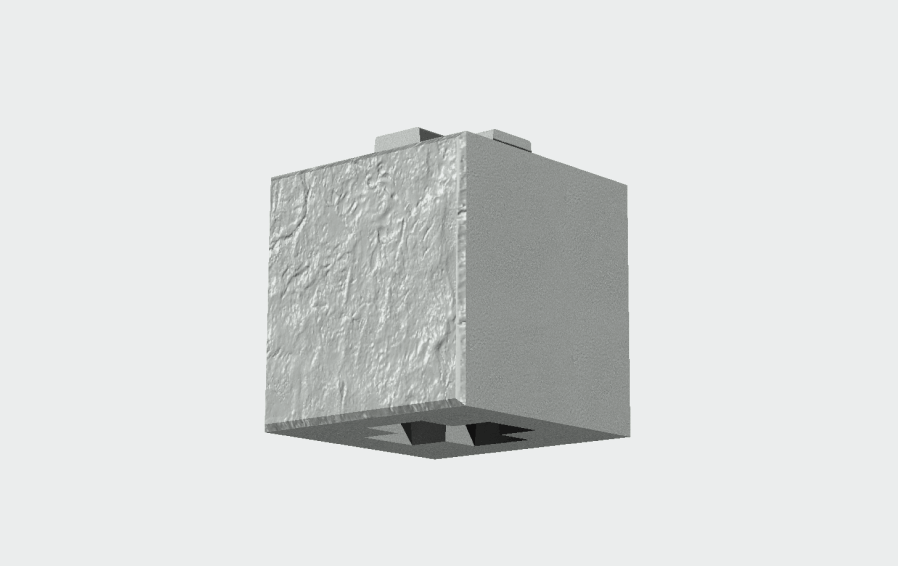

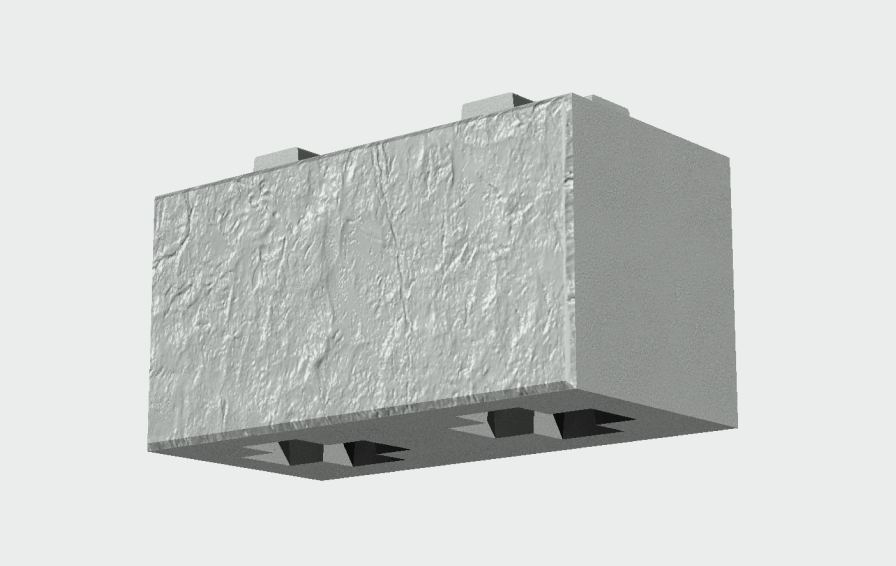

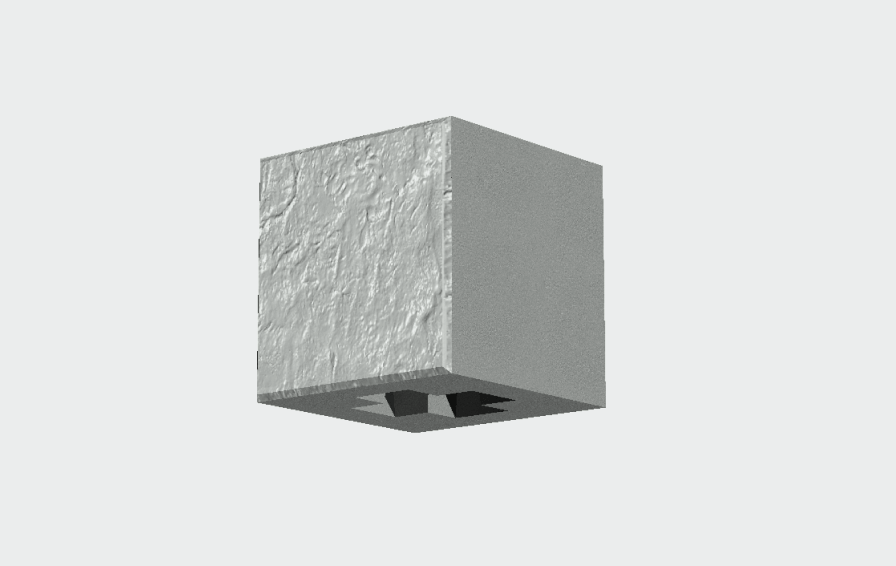

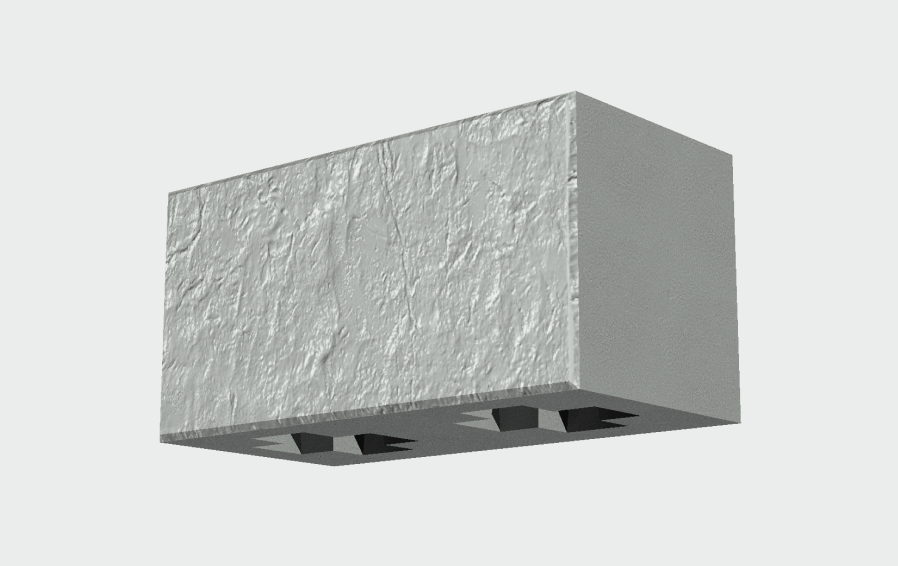

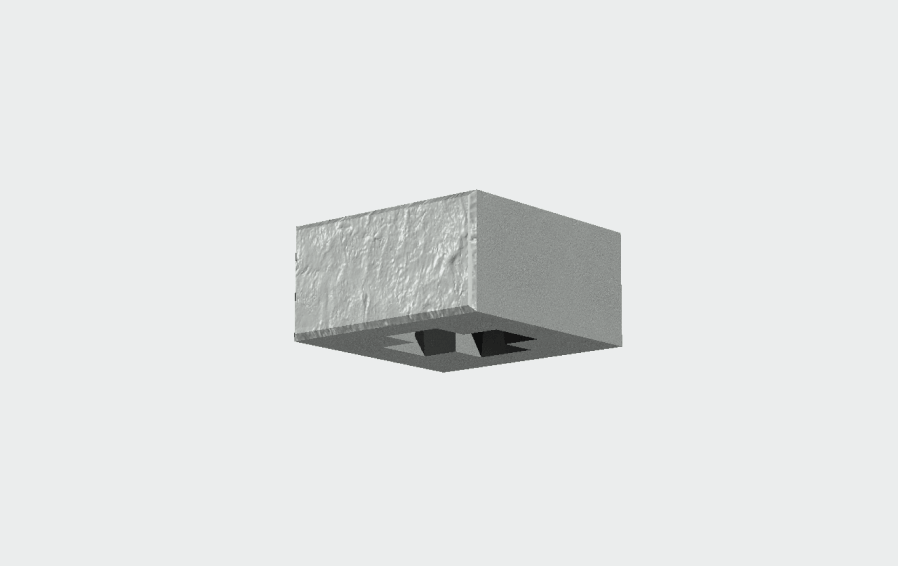

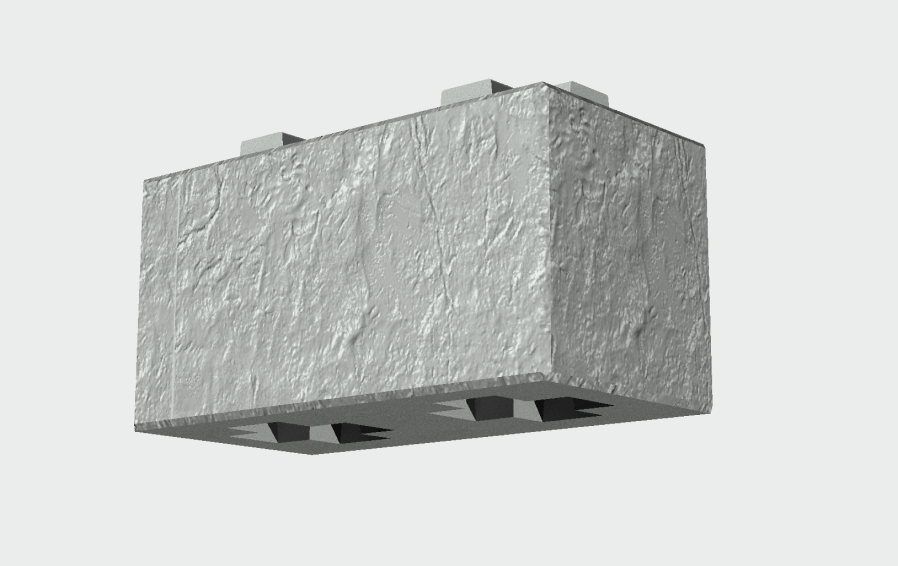

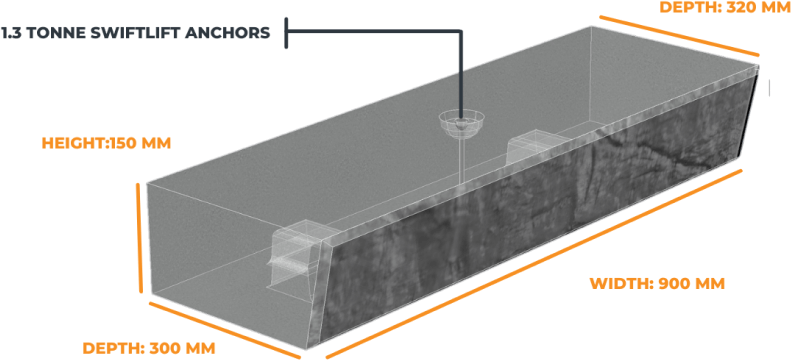

Each premium block includes a shear key, and a lifting pin, all designed to enhance structural strength and integrity. The shear key transfers shear forces from lateral loads between the structure and the key but does not resist overturning forces, which are managed by the weight of the concrete block.

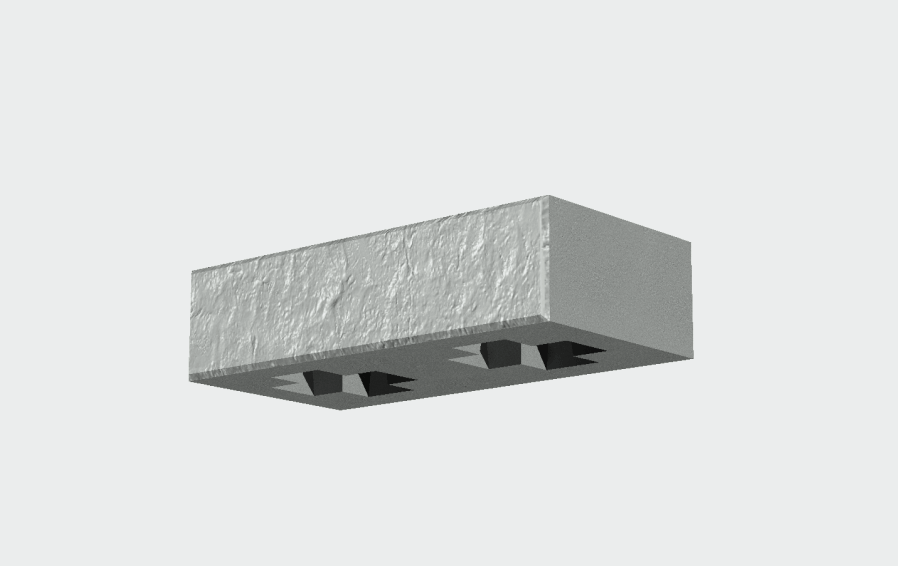

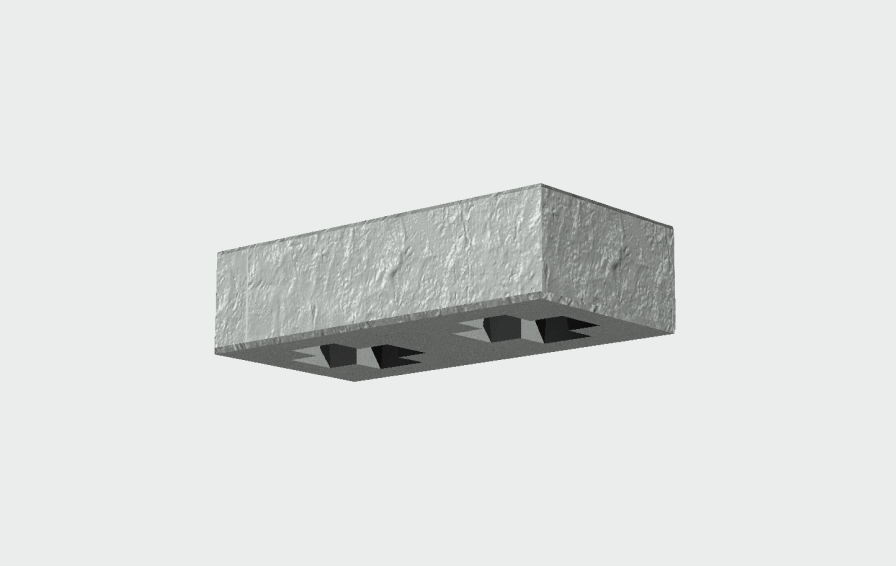

Base Blocks

Base blocks provide a sturdy foundation for your wall, tailored to the specific height requirements of your structure.

W: 800 x D: 800 x H: 400Mm

W: 800 x D: 1200 x H: 400Mm

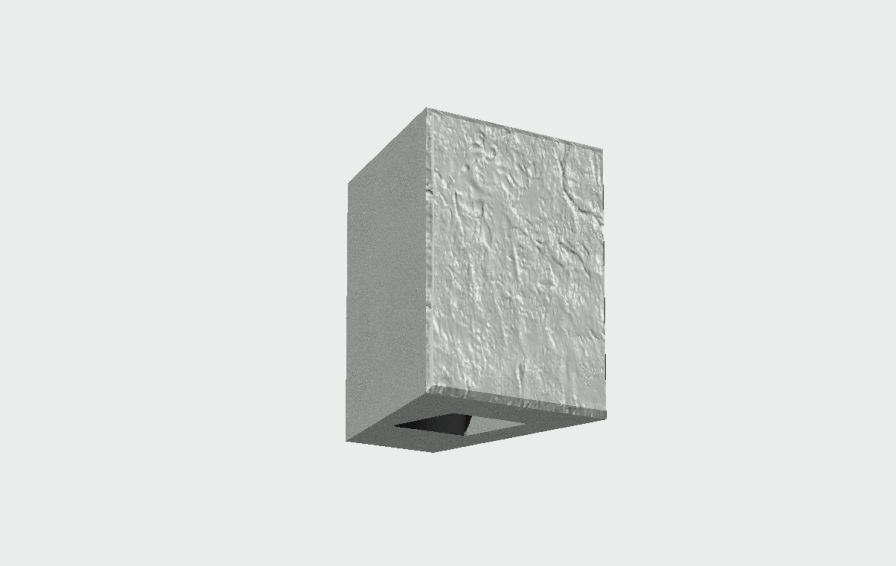

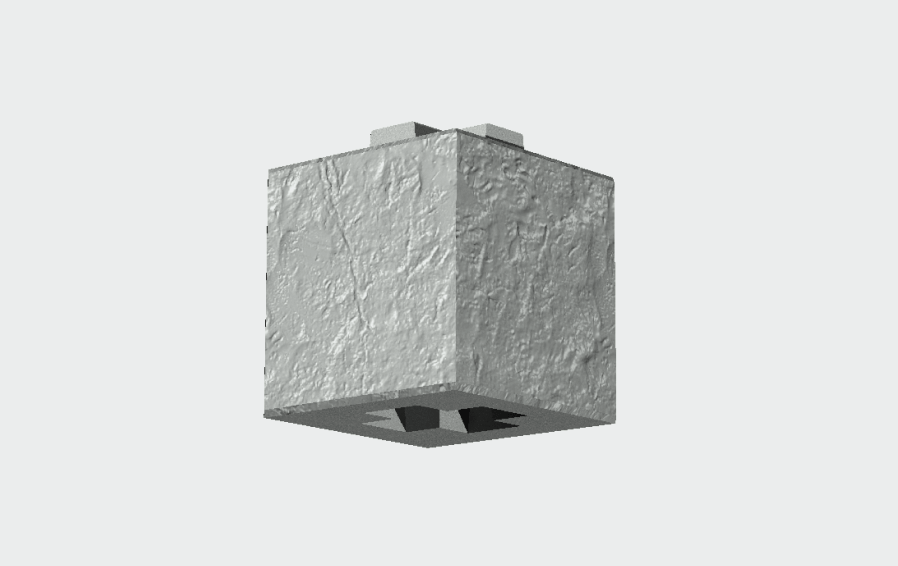

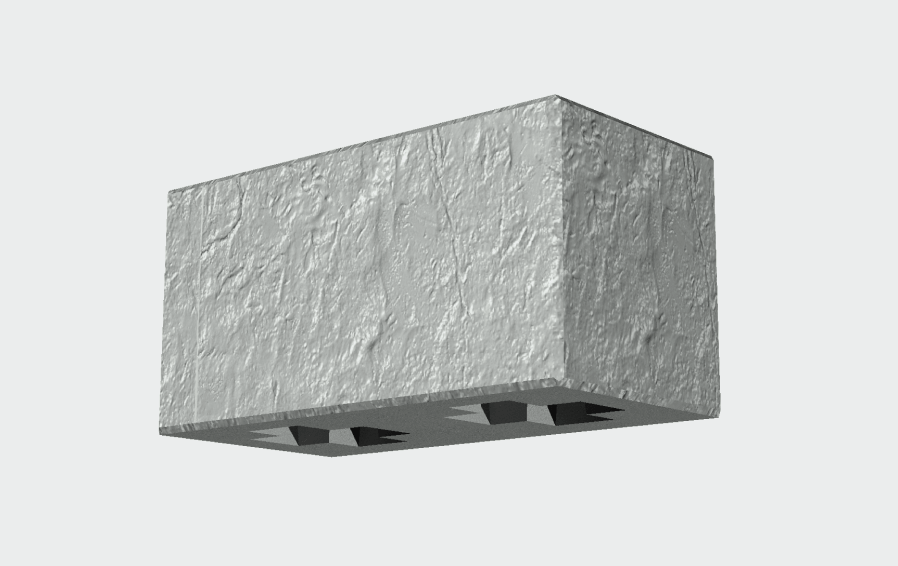

Standard Blocks

W: 400 x D: 400 x H: 400Mm

W: 800 x D: 400 x H: 400Mm

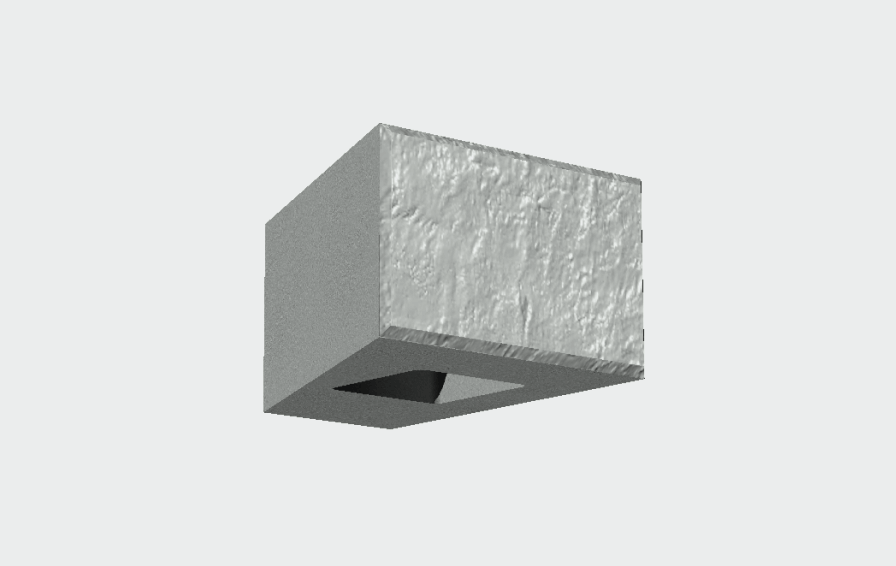

Flat Top Blocks

W: 400 x D: 400 x H: 400Mm

W: 800 x D: 400 x H: 400Mm

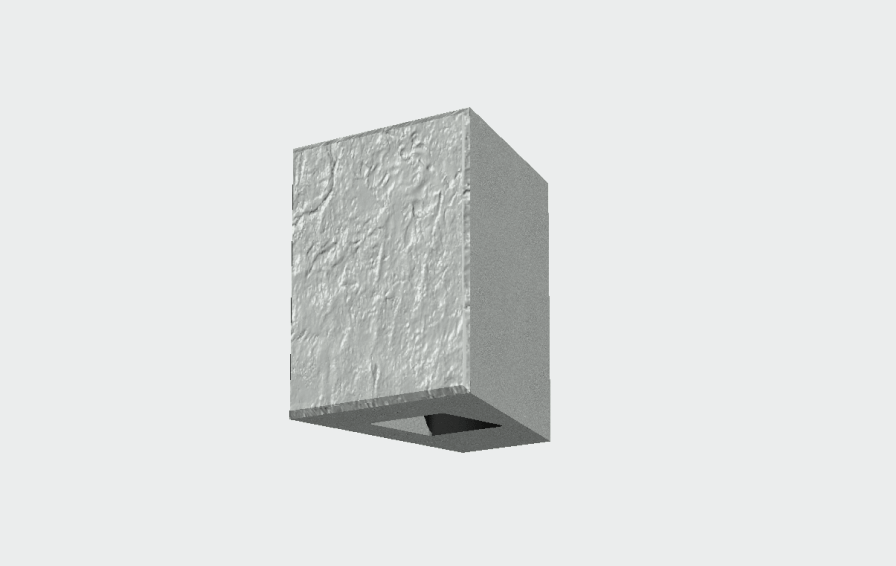

Capper Blocks

W: 400 x D: 400 x H: 200Mm

W: 800 x D: 400 x H: 200Mm

Wedge Blocks

Wedge blocks are crafted to incorporate smooth curves into wall designs seamlessly.

Right Ended

W: 400 x D: 400 x H: 400Mm

W: 400 x D: 400 x H: 200Mm

Left Ended

W: 400 x D: 400 x H: 400Mm

W: 400 x D: 400 x H: 200Mm

Double Ended Blocks

These blocks ensure seamless integration and a cohesive finish across the retaining wall. They can be used for tapered transitions or wall ends, with options for both right and left ends, providing flexibility for your retaining wall design.

W: 400 x D: 400 x H: 400Mm

W: 400 x D: 400 x H: 400Mm

Right Ended

W: 800 x D: 400 x H: 200Mm

W: 600 x D: 600 x H: 600Mm

W: 1200 x D: 600 x H: 600Mm

Left Ended

W: 800 x D: 400 x H: 200Mm

W: 600 x D: 600 x H: 600Mm

W: 1200 x D: 600 x H: 600Mm

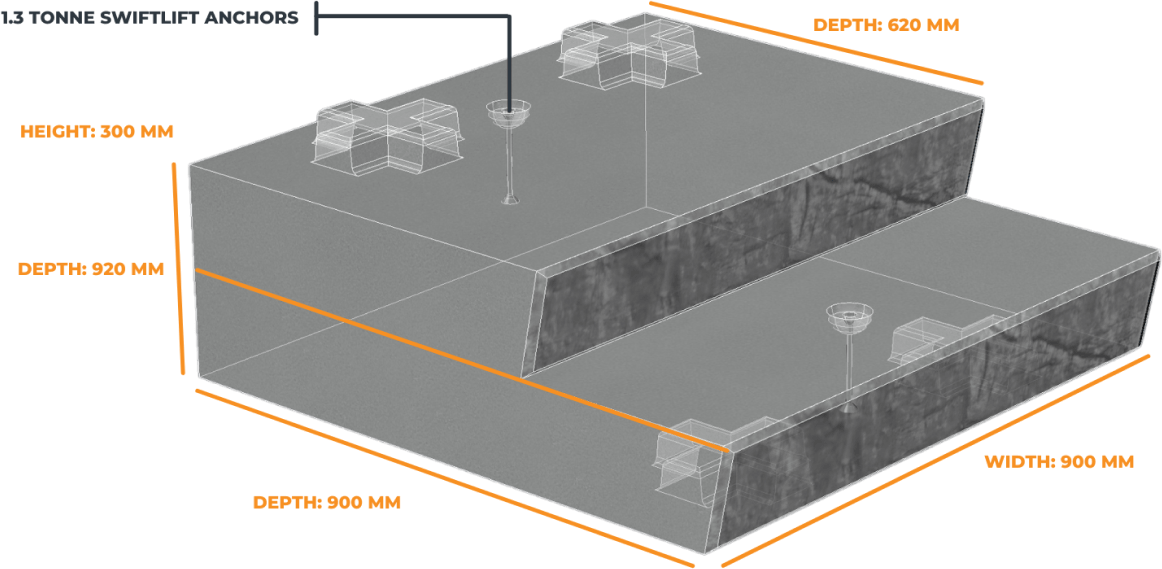

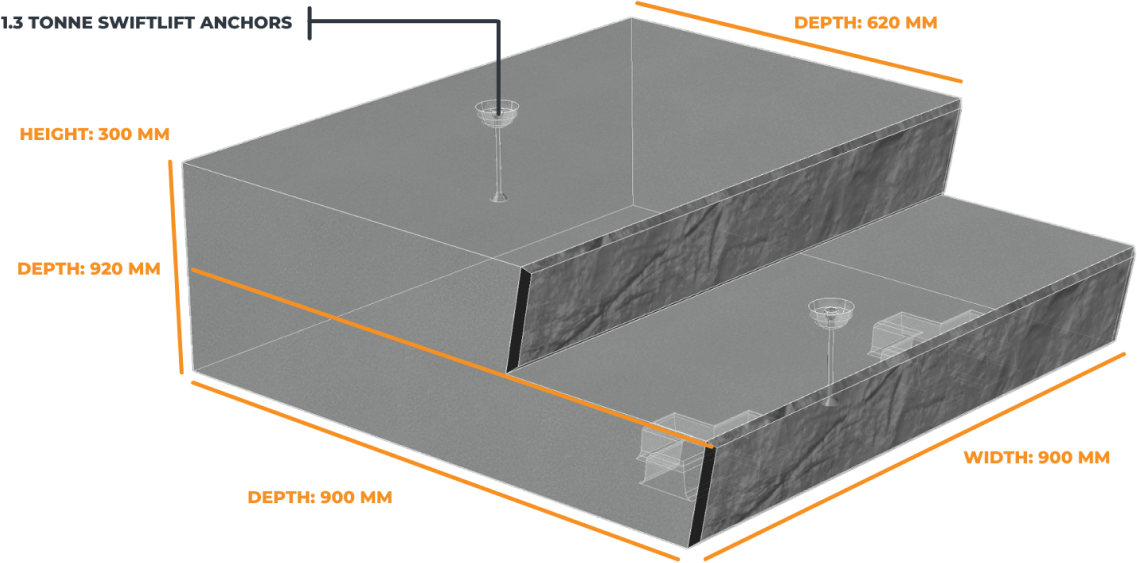

Staircase Designs

STAIR CAPPER

STAIR STANDARD

STAIR FLAT TOP

INTEGRATING STONEBLOC INTO ROCSCIENCE RSWALL BLOCK LIBRARY

First download the CSV file. To install the library, please follow these steps:

In RSWall, go to the Wall tab.

Click the Define Wall Units button.

In the new window, click the pencil icon (Edit Manufacturer Library) in the top right.

In the next window, click the User Defined Manufacturers button.

Click the + Add Library button and select the attached CSV file to upload.