Pokeno’s uneven landscape makes retaining walls a must for many homeowners. Steve & Sopa are part of this group, searching for a solution for their newly built home.

After moving into their home a few months back, Steve and Sopa wanted to start improving their outdoor space. In Pokeno, rolling hills are often part of the landscape - meaning retaining walls are vital for creating usable space The main areas of focus were the driveway and the entertainment area that looks out towards the paddock.

Initially, timber was considered because they’re often seen as the go-to for retaining walls. With supply chain issues, higher installation costs, and many of their neighbors having timber retaining walls, Steve and Sopa searched for something different. To set themselves apart, they looked for a timber alternative.

After doing some research, they came across Stonebloc on Facebook. What stood out with Stonebloc was that it was “unique and something a bit different” (Steve and Sopa). They didn’t like seeing the fence posts of timber retaining walls, and Stonebloc “removed the obscured appearances the timber wall designs have”.

“We feel our home is one of our greatest assets. Stonebloc raises the looks and value of our home for us and our family’s future to enjoy”

How Stonebloc improved Steve & Sopa’s property:

- Created a retaining wall by their driveway, where fruit trees sit above

- Created a retaining wall that looks out at Pokeno farmland, doubling as an attractive entertainment area

Designing beautiful retaining walls with Stonebloc is simple from installation to maintenance - the perfect solution for homeowners. Better yet, it’s made for New Zealand meaning it fits in well with the country’s landscape.

Steve & Sopa recommend Stonebloc for homeowners as “it’ll make your home and landscape stand out and add value”. The retaining walls last generations, providing an everlasting solution.

Wanting to add value to your home? Get in touch to build Stonebloc retaining walls

The Morrison family is well-known in the Warkworth community, having owned land near the township for many years. In recent years Bevan Morrison has been converting the family land to industrial and commercial developments to support the town's rapid growth.

In April 2021, Bevan reached out to Envirocon looking for some blocks for his farm. Once Bevan heard about the unique Stonebloc block, he started to explore using it on his upcoming commercial development.

That development required a retaining wall to support a carpark. Council requirements also meant the wall needed to have street appeal and serve as a wheel stop - Stonebloc provided the ideal solution.

(Car parked behind the Stonebloc retaining wall that serves as a wheel stop)

Why Stonebloc was chosen

For his retaining wall, Bevan was looking for something that was “functional that also looks good”. He was also looking for something that was fast to install and could be done with a digger.

Stonebloc was chosen for a few reasons:

- The blocks are a larger square meterage compared to other modular retaining wall systems, meaning installation is faster

- The blocks are flexible with their facia design. If Bevan wants an exposed facia or oxide blocks for future projects, it can be done

- The blocks can be installed with a small digger

- “Looks more real than other options out there”

- “Support was really good and responsive”

Comparison to other retaining wall options

With commercial properties, an important aspect of retaining walls is longevity. After looking into alternative systems such as timber retaining walls and other concrete modular walls, Bevan chose to go with Stonebloc.

Although timber retaining walls came out slightly cheaper for his 800mm wall, Bevan wants to keep this property in the family for generations. For this, walls need to last and require little maintenance. Timber retaining walls after 20 years start to deteriorate, and you don’t get this with concrete. For Bevan, choosing Stonebloc at the beginning beats out the lower cost and repeated maintenance of timber retaining walls.

“Slight premium you pay over timber is well worth it to look good” - Bevan Morrison

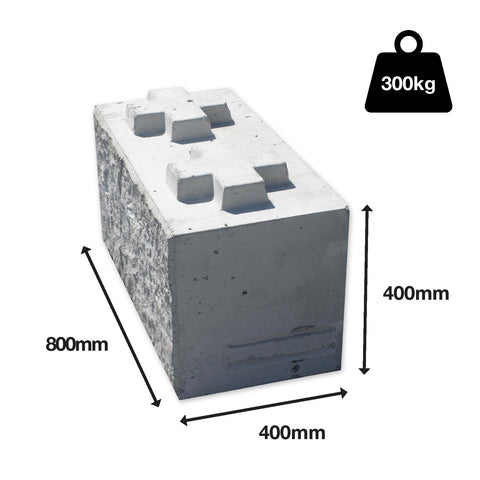

One of the other reasons Bevan choose Stonebloc was the size of the blocks. Stonebloc allows commercial developers to install with a digger. The standard block size (800mm L, 400mm W, and 400mm H) are in between that of the competitors sizing. For the application of the car park, the Stonebloc sizing was the perfect fit.

Why Bevan Recommends Stonebloc

As a developer/business owner, Bevan chose Stonebloc as it will look good forever, giving him reassurance his investment is worthwhile. It means that as this property passes down the family, they don’t have to worry about maintaining the wall.

Bevan loves companies that are trying something new that has “local product and local people”. He’s definitely use it again and would recommend it for applications like this.

Stonebloc’s flexibility lends to creative design. There is no better example of this than the South Taranaki District Council’s (STDC) seawall at Opunake Beach.

Opunake Beach is a popular beach in the South Taranaki District. It’s a well-known spot for surfers, even being called “Home of the Big Wave”. Here, an existing crib seawall collapsed making it no longer fit for purpose. This caused risk to the community, creating a need for a durable replacement that can withstand erosion and rising sea levels. Jayson, the Projects Engineer at STDC describes the old seawall:

“ The previous lattice wall design was prone to disintegration brought about by sea water waves coming through. The structure was built in 1995.”

From what Jayson has stated, it is clear the new seawall needed to meet strict criteria - the main criteria being erosion protection.

Stonebloc was chosen as it met STDC and the community’s needs. It ticked off a lot of the boxes, including:

- It can be built fast, reducing potential health and safety risks

- It can withstand the coastal environment

- It can be built over service outlets

- It looks good

- It provides “Quick installation and it's clean-looking aesthetic wise” - Jayson, STDC

Erosion protection was one of the most important aspects of this project. After years of coastal activity, extreme water levels played a large part in the collapse of the crib wall. Chan Zhi Han, Chartered Engineer from Resilient Structures found that backfill had been washed away during tidal/storm events which left the concrete elements of the crib wall unsupported. It was recommended the future seawall extend the drainage outlets seawards. This ensures the base will not be undermined, leading to a risk of local destablisation.

(Drainage pointing seawards for the Stonebloc wall)

Another important element considered was the design pressure. After calculating 8 different designs, Chan recommended a tiered Stonebloc seawall. This is because it provides reassurance of high-quality protection with the lowest amount of design pressure. Chan also noticed evidence of beach scraping which may have contributed to the original wall's damage. The likelihood of damage being made by mechanical equipment was considered with the Stonebloc design, along with the need for erosion protection.

(On the left is a standard Stonebloc block. On the right is one of the custom blocks that was used for this STDC project)

The result of creating custom blocks was a strong seawall with a functional seating area for beach-goers.

(A beach-goer sitting on the tiered seating of the Stonebloc Seawall)

With Stonebloc, you can make your designs come to life. Get in touch with us to start creating.

Hamish from HP Works Ltd is an experienced Stonebloc Installer, and has recently completed a Stonebloc project in Campbell’s Bay.

Prior to Stonebloc being installed, this homeowner had timber retaining walls. Over time (it’s estimated this wall was built in the 1970s), this timber retaining wall failed, creating an urgent need for the customer’s retaining wall to be replaced.

Timber was out of the question. With its failure in the past, the customer was looking for a more durable option - one that could stand the test of time. Stonebloc was chosen due to its strength and high quality aesthetic.

The previous retaining wall created a terraced space - with a lower and upper section. To create something more usable, the customer decided to remove the terracing entirely, choosing to have just one supportive retaining wall across the boundary line.

(Before this area had 2 levels. With this new retaining wall, the customer requested there to be no terracing so they had more usable space. Earthworks was completed, pushing the retaining wall to the edge of the boundary line)

Here's what Hamish had to say about this project:

"The use of Envirocon's Stonebloc range allowed me to build a solid low maintenance retaining wall that my clients and their neighbors approve of."

Wanting a Stonebloc wall similar to this? Get in touch!

B & T Earthmoving was contracted to make install a retaining wall on high-density development in Epsom, Auckland. This project came with difficulties that traditional retaining wall solutions would have difficulty adapting to. Stonebloc was easily able to work around these difficulties and offer a well-designed, presentable wall.

A prominent feature in this site was bedrock, meaning traditional poles and footings were not an option. For ground like this, retaining wall solutions need to sit upon as opposed to being dug into. Not only was bedrock an issue, but so was tight access. The retaining wall solution needed to have the ability to be built on the boundary line.

Both of these factors - bedrock and tight access - can be remedied by Stonebloc. The fact that Stonebloc could be installed quickly and could be laid on a bed of metal were the main reasons the contractors chose the product.

From the contractor’s perspective, installation is very simple and fast. Unlike their solutions such as masonry, there is no grouting or gluing. The blocks stack together much like LEGO.

Here what Phil from B & T Earthmovers had to say about the project

If you're needing a retaining wall solution that can adapt to tight sites and tough ground, look no further than Stonebloc.

Stonebloc is a gravity retaining wall system that’s designed for contractors to provide fast installation with minimal labour. The result is a system that delivers the speed and durability of precast concrete, for less money.

Phil of B&T Earthmoving used Stonebloc for the first time at a challenging site in Auckland. “It was a really rocky site, as well as tricky and tight,” he explained. Despite it being the first time the company had used Stonebloc, they soon found it was a lot easier to set up and a lot quicker to install than anything they’d used before.

They found that good preparation was key to delivering a good looking and long lasting wall. While no grouting or gluing was needed between the blocks, making it a lot easier and quicker to construct, initial site preparation was really important. The ground had to be levelled correctly before the first blocks were laid, but once that was sorted “set up was easier and a lot quicker,” he said.

He feels the interlocking blocks with their decorative fascia look really good. Stonebloc walls can be built right up to the boundary, which maximises the usable area for homeowners – something that’s increasingly important in today’s smaller lot sizes. Stonebloc’s solid, upcycled concrete blocks offer a unique interlocking design that provides shear strength in both horizontal directions.

Neville is a site foreman at ICB, and his team used Stonebloc for the first time on a big project that required 729 lineal metres of retaining walls. He also found that good base preparation was the key to a quick and easy install – easier than other stone walls to install, too.

“It’s like a big kids’ LEGO set,” he said. Using vertical weight [gravity] maximises stability, which means Stonebloc retaining blocks lock together easily - and stay together.

“You have to get the bottom blocks right first, and they have to sit properly. Then you can work your way through, and up, as you go. It’s easy, but you have to take time to make sure everything’s at the correct angle.” This allows the wall to take the loadings and remain stable and straight, especially on a sloping site.

This project used Stonebloc’s newest product - double-ended blocks - as well as ones specially-manufactured for this job that allowed for specific angles at site boundaries.

Stoneblocs are made from solid concrete, and in wet weather any building site becomes really muddy. They found that storing the pallets of blocks close to where they were installing them, saved a lot of time and energy.

The finished project was something the whole team was proud of. The ICB team includes:

- Arnulfo Nartea - Forman & Digger Operator

- Joey Gurrea - Skilled Digger Operator

- Adam Suaesi - Skilled Labourer & Digger Operator

- Teremai DIxon - Skilled Labourer & Digger Operator

- Anaru Morris - Forman & Digger Operator

- Chris Endt - Skilled Labourer & Digger Operator

- Perry Carr -Skilled Labourer & Digger Operator

(Some of the ICB Team who built Stonebloc walls in Auckland)

The Stonebloc retaining wall system is proven to withstand significant loadings – it’s been independently tested by the University of Auckland School of Engineering. Stonebloc’s consent-ready designs use conventional engineering principles and cover walls 0-12kPa and up to 2m high.

Want to find out more? Read our 9 Top Tips for Installing Stonebloc.

Contact us now to find out how you can work smarter with Stonebloc on your next retaining job. It’s a timeless solution the client will love as much as you do.

Williams Corporation has a reputation for developing high quality, affordable homes throughout Auckland, Wellington, and Christchurch. In ten years of operations, Christchurch based Williams Corporation has grown to be one of NZ’s largest residential developers.

The secret to their success is the ability to maximise land utilisation, focusing on high density infill housing. Stonebloc has proven to be an excellent retaining wall system to accommodate this type of building. Stonebloc walls can be built vertically on the boundary and deliver unparalleled durability at a price point similar to timber walls.

When Williams Corporation developed nine dwellings on an 800sqm site at St Leonards Road, Kelston, Auckland their long term civil contractors DiggersNZ were able to install the walls. DiggersNZ is a national company specialising in foundation excavations, site cuts, backfills, trenching and more. Doing away with the need to bring in specialists retaining wall contractors, Stonebloc provided Diggers NZ with the flexibility to progressively build walls as required.

Mike Hawke is DiggersNZ Project Site Manager and like Williams Corporation, he’s a fan of the Stonebloc system. “We’re familiar with the principles involved with assembling Stonebloc,” he said. The solid concrete blocks can be stacked easily and need neither glues nor grouts to hold them in place, meaning a standalone gravity wall can be constructed very quickly – saving assembly time and maximising value for money.

Each Stonebloc is 400mm thick solid concrete, and similar to well-engineered LEGO it uses a unique design and interlocking shear key for an exceptionally robust wall. The textured fascia of Stonebloc comes in a range of patterns, providing visual interest and positive placemaking for both residents and visitors.

“Stonebloc is a win-win system”, explains Jack Bright from Envirocon. “It’s a win for developers as it delivers a superior wall system at, or close to, a timber price point. It’s a win for council’s as it delivers a resilient structure that can be non-destructively dismantled in the future for maintenance or access to utilities. It's a win for civil contractors as it's a locally manufactured, high productivity system.”

Civil contractors Dempsey Wood installed Stonebloc to divide the terraced super lots at Ara Hills, a brand new, 84ha subdivision on the steep hills 3km above Orewa town centre, Auckland.

When owners AV Jennings Properties Ltd began work on Stage 1 of the development, Envirocon’s Stonebloc retaining system was specified to retain and divide the super lots. Terracing was an obvious way to maximise the available land and prepare these lots for sale, and Stonebloc was a convincing choice for the job.

This was a big job - engineers had called for a combination of 400mm and 800mm-thick blocks to be used, across different three types of wall. One wall type was 800mm tall (550mm above ground), another 1200mm (950mm above ground), and the third 1600mm (1350mm above ground). Spine walls were 105m long, and the longest walls coming off the spine were 30m. Thousands of Stonebloc blocks were required. Dempsey Wood were the civil contractors, and it was the first time Project Manager Ryan Lunn had used this system. “I was told it would be like putting LEGO together,” he says.

On the relatively steep grades it had been anticipated that construction would be a bit more complicated than that, but once foundations were in place and installation and back filling was completed, the job was absolutely straightforward, says Ryan. “There were lots of complex issues to this job, including our need to use specialised polystyrene fill at some points to reduce weight on the sandy soils. “There was a lot of weight, especially on the upper lot for each wall. It was important to design and install specialised EPS foam as backfill material to reduce weight while still meeting structural requirements. And of course aggregate/scoria was required to allow drainage to occur.”

But once everything was set up properly, Stonebloc was really easy to install. “The walls themselves were all built on flat ground (one percent) slope,” explains Ryan. “The slopes of the surrounding roads and lots were up to six percent. All the walls were built on 200mm concrete foundations due to the soft ground underneath, and our building them in winter. “The thousands of Stonebloc blocks were easy to install and work with – they’re a good option for retaining walls. The product looks nice at the end, and it’s easy to adjust onsite.” An independent University of Auckland report provides conclusive evidence that correctly-installed blocks can withstand <35.6 kN lateral loadings from, for example, active earth pressure.

The report also showed evidence of the out of plane behaviour and unfactored restoring moment capacity of this type of wall, giving engineers and contractors additional confidence in Stonebloc’s performance over many years – making it ideal for the Ara Hills project.

Envirocon were not surprised by the results. “Our design approach is guided by the rule of simplicity, because simple products are usually the best – they’re also fast for people to learn and are easy to use,” says Envirocon’s Sales and Marketing Director Jack Bright. “Stonebloc is a unique system that not only delivers a strong performance in situ, but it’s good looking as well.”

Stonebloc is usually seen as a relatively low-standing (up to two-metres tall) and cost effective option for residential retaining walls. It can be installed right on a boundary, and its architectural fascia designs provide visual interest beyond the standard concrete or timber faces most often seen.

Overview

Jalcon Homes builds modern well-constructed homes in a variety of residential settings with land and home packages. As a developer, Jalcon performs two functions, developing superlots and building homes on individual lots. This case study demonstrates how a unique set of circumstances demanded a different approach to solving the problem of maximising the building envelop in a

residential setting with retaining walls.

(Jalcon Home's Hobsonville Point)

This case study is about Jalcon Homes' Hobsonville Point development. Jalcon wanted to maximise the building footprint and comply with council regulations creating retaining walls that not only looked aesthetically pleasing but also provided the necessary function. The retaining wall needed to be built completely at the edge of the unit title and deliver a loading strength that meant heavy traffic could drive alongside the edge of the structure.

Traditional timber retaining walls utilise more land than is desirable and take considerable time for labourers to install. Stonebloc minimises the building envelope and its interlocking system makes for a fast and stable platform when constructing.

(On the left is a timber retaining wall, and on the right is a Stonebloc retaining wall)

The Challenge

Jalcon Homes had two superlots (21 & 25 unit titles) for high density housing. In both cases there were shared driveways and parking bays which back onto individual land owner sites. The retaining walls ranged in height from 0.4 metres to 1.7 metres high and were up to 85 metres long.

Fencing was to be erected on top of the retaining walls to give individual unit title holders’ additional privacy. This fencing needed to be erected quickly and in a simple fashion. Stonebloc retaining wall cappers and flat top blocks were used to achieve this. With height variations along the retaining wall structure a custom build plan was developed in conjunction with Jalcon, its engineers and the

subcontract installer.

These modern homes needed exterior landscaping to match the housing design. Stonebloc retaining walls create a backdrop that blends into this setting and offsets planting and functional aspects of urban living.

The Result

Stonebloc was able to be used with a simple gravel base for its gravity walls system, yet still providing the loading capacity to allow heavy traffic along driveways and into parking bays.

Stonebloc can be built quickly with lower labour costs due to the modular nature of the interlocking system. Cantilever walls were also available as required.

Vertical walls were erected at the edge of the boundary to maximise land use and build within a unit title holder’s envelope.

A total of 855 blocks were required and a competitive pricing model was achieved when compared against other building materials and methods. Overall Stonebloc met and exceeded the requirements for Jalcon.