Interbloc is primarily a gravity based precast modular wall system. This means the combined mass of the blocks, supported by Interbloc’s unique shear key design, resists forced pushing against the wall. For higher walls, or higher loads, vertical reinforcing can be used to increase the capacity of the wall. All Interbloc blocks incorporate 600mm diameter reinforcing ducts at 600mm centres for speed and ease of installation.

(On the left is an Interbloc gravity wall, on the right is a vertically reinforced Interbloc retaining wall)

What is vertical reinforcing?

Vertical reinforcing involves a steel rod being inserted through the reinforcing ducts in the blocks and glued into the underlying concrete foundation. This combines the wall and the foundation into one super strong structure, which means the wall is able to withstand much higher loads. An alternative to tying the blocks to the concrete slab is to tie the wall together using a washer and nut at the top and bottom of the wall.

The first step of installing vertical reinforcing is for a short piece of threaded steel rod, a ‘starter bar’, to be glued into the concrete slab. A coupler is screwed onto the starter bar. The balance of the blocks are put in place. A longer piece of threaded steel rod, a ‘mainbar’, is inserted from the top of the wall and screwed into the coupler. The kit is then tied off at the top of the wall using a nut and washer.

Interbloc Fixing Kit Components and Features

“Fixing Kit” is an Envirocon term that refers to the combined components required to tall the wall together, or to the concrete foundation. There are 2 fixing kit types: standard and top and bottom.

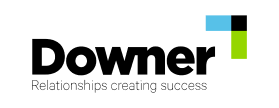

Standard Fixing Kit

A Standard Fixing Kit consists of a starter bar epoxied into the underlying

foundation. Once the blocks have been installed, the main bar is inserted through reinforcing ducts cast into the blocks and connected to the starter bar using a coupler. Finally, the main bar is tied off at the top of the wall using a nut and washer.

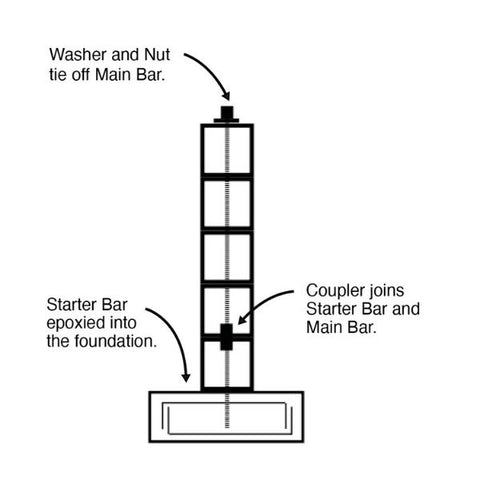

Top and Bottom Fixing Kit

A Top and Bottom Fixing Kit ties the blocks in a wall together; however, it will not tie the blocks into the underlying foundation. A top and bottom fixing kit is installed post installation by inserting a main bar through the blocks with a nut and washer tying off each end.

Fixing Kit Components

| Epoxy It is most common for Fixing Kits to be epoxied into the concrete foundation - Chemset C8 Extreme or Hilti Hit-500RE are common epoxies. |  |

| Starter Bars The starter bar is a short piece of threaded reinforcing bar epoxied into the underlying foundation. |  |

| Coupler The Coupler joins the Main Bar to the Starter Bar |  |

| Main Bar The Main Bar is a length of reinforcing bar that forms the core part of the vertical reinforcing kit. The Main Bar is joined to the Starter Bar using a Coupler. |  |

| Washer and Nut The Washer and Nut tie off the top [and bottom in the case of a top and bottom fixing kit] of a wall. |  |