Sustainability at Envirocon

How Envirocon Leads in Sustainable Solutions

PRODUCT STEWARDSHIP

Product Stewardship encourages manufacturers to take end-of-life responsibility for products, promoting resource-efficient, waste-minimising designs. For ready-mix concrete, this means capturing excess certified concrete and up-cycling it into durable, reusable precast products.

Envirocon leads this approach in New Zealand as the only construction-related stewardship scheme accredited under the Waste Minimisation Act 2008.

Our approach maximises resource use by reducing waste and designing products for repeated reuse.

This strategy extends the carbon footprint over a longer product life, making concrete sustainability practical and impactful.

LOW CARBON CONCRETE PRODUCTS

Our innovative design brings unique benefits to customers:

- Speed of installation—reducing labour costs;

- Durability—built on sound engineering for safety and structural integrity;

- Flexibility—allowing modifications as needs change, enhancing resource efficiency.

At the end of a structure’s life, our products can be dismantled non-destructively and reused repeatedly. Plus, our buyback guarantee underscores our confidence in their quality. The result? Sustainable, cost-effective precast solutions.

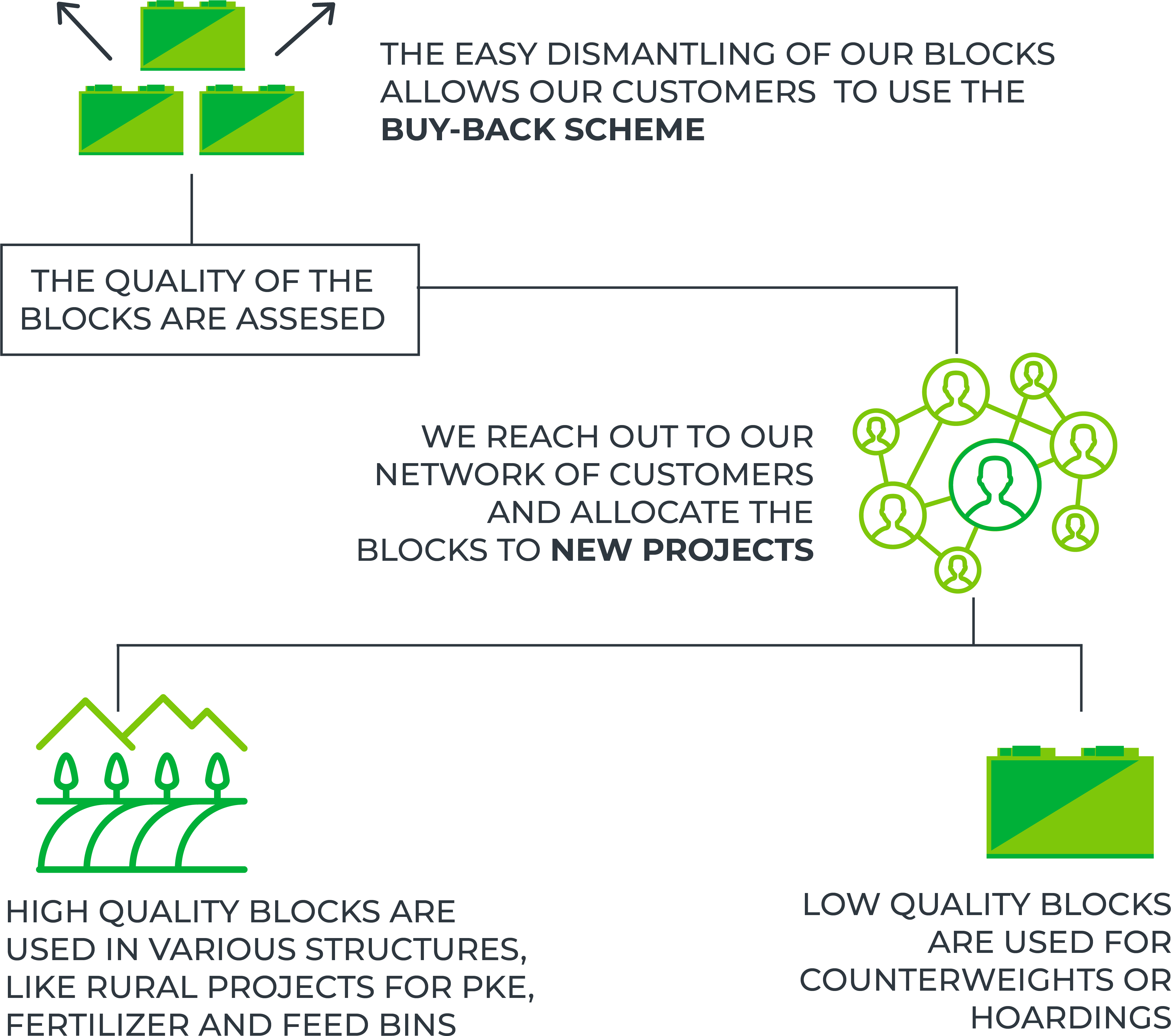

DESIGNED FOR DECONSTRUCTION

Our precast concrete blocks are designed for longevity and reuse. When a structure reaches the end of its life, our products can be dismantled without damage, allowing them to be repurposed for new projects time and again. This adaptability not only supports sustainable construction but also maximises the value of each product over its extended lifecycle. To reinforce our commitment to quality and durability, we back our products with a unique buyback guarantee—ensuring customers can confidently invest in sustainable solutions that truly last.

BUYBACK GUARANTEE

Envirocon’s Buyback Guarantee for Interbloc is all about closing the loop on waste for good. It is essentially a second-hand trading service, we take the blocks off your hands and offer them to our database of customers who prefer second-hand blocks. Some basic terms and conditions apply.

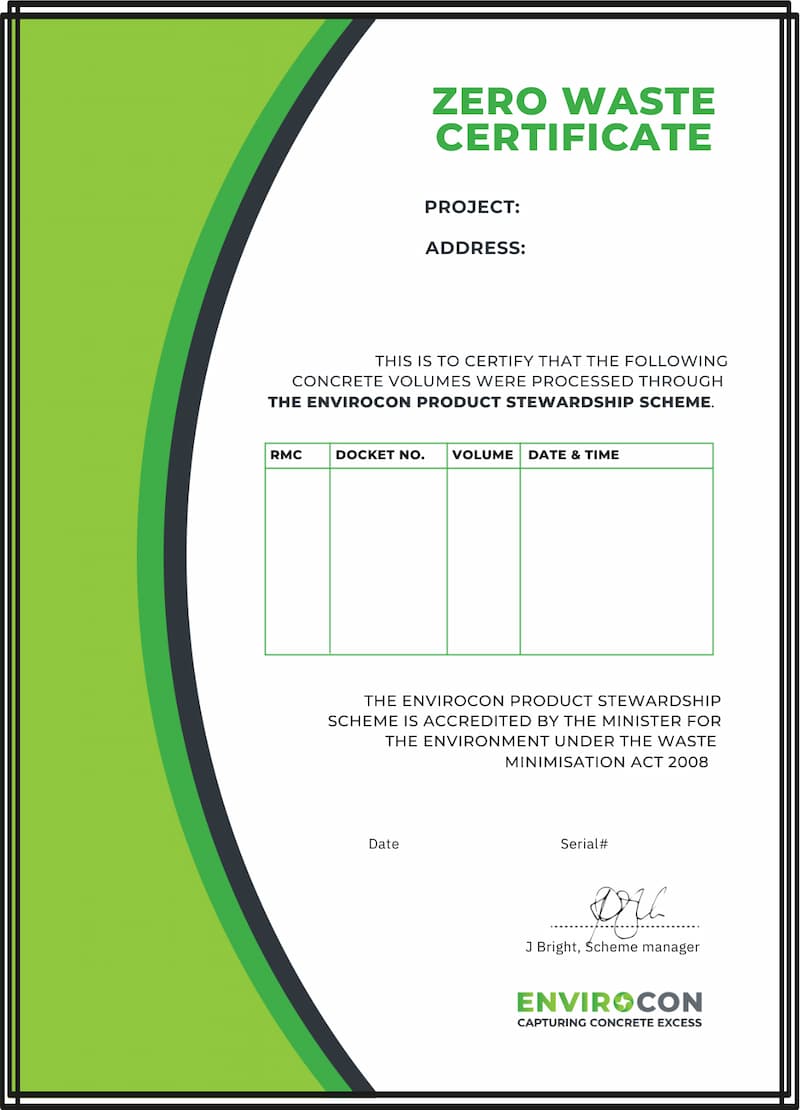

Envirocon Zero Waste Certificates:

The Gold Standard in Zero Concrete Waste

Envirocon, accredited by New Zealand’s Waste Minimisation Act 2008, offers the only zero-waste solution for managing excess concrete from ready mix pours. Through a network of collection sites, Envirocon captures leftover concrete and provides valuable data to help members cut costs, maximise asset use, and improve load charging accuracy. Membership supports sustainability goals, enabling companies to meet zero-waste requirements for IS Rating and Green Star certification.

What are Envirocon Zero Waste Certificates?

These certificates are a record of waste concrete processed by Envirocon on behalf of its member ready mix concrete suppliers. Envirocon operates under the Waste Minimisation Act 2008, ensuring responsible and sustainable practices.

Why Choose Concrete from an Envirocon Member?

Verified Sustainability: Unlike non-members who may charge for concrete returns without proof of sustainable processing, Envirocon members provide certified evidence of their commitment to zero waste.

Environmental Stewardship: By choosing Envirocon members, you support a scheme that actively diverts waste from landfill and promotes a circular economy.

Meeting Sustainability Goals: Zero Waste Certificates can be used to demonstrate your commitment to sustainability in various rating schemes.

Responsible Choice: With rising waste disposal costs and levies on construction materials, choosing sustainable concrete is a financially and environmentally sound decision.

Make a difference. Choose concrete from an Envirocon member and ask for your Zero Waste Certificate.

OUR PARTNERS

Efficient Waste Solution for

Ready Mix Concrete COMPANIES

Envirocon, accredited by New Zealand’s Waste Minimisation Act 2008, offers the only zero-waste solution for managing excess concrete from ready mix pours. Through a network of collection sites, Envirocon captures leftover concrete and provides valuable data to help members cut costs, maximise asset use, and improve load charging accuracy. Membership supports sustainability goals, enabling companies to meet zero-waste requirements for IS Rating and Green Star certification.

PARTNER WITH US

Want to cut costs, improve load accuracy, and meet zero waste goals? Fill out the form below, and our team will get in touch!

DATA INSIGHTS

Tracking data on large civil construction projects is challenging, often relying on manual data entry. Envirotrac simplifies this process for sustainability teams and project managers, providing real-time data solutions to track and report on waste diversion effectively. Our software enables easy monitoring of excess concrete, helping prevent waste and supporting your efforts to achieve zero waste to landfill.