Interbloc+ is a premium, locally manufactured wet cast precast concrete retaining system engineered for strength, speed, and sustainability.

Interbloc+ is a premium, locally manufactured wet cast precast concrete retaining system engineered for strength, speed, and sustainability. Designed with the asset owner, engineer, and contractor in mind, Interbloc+ delivers a robust, gravity-first retaining solution that is both cost-effective and visually refined.

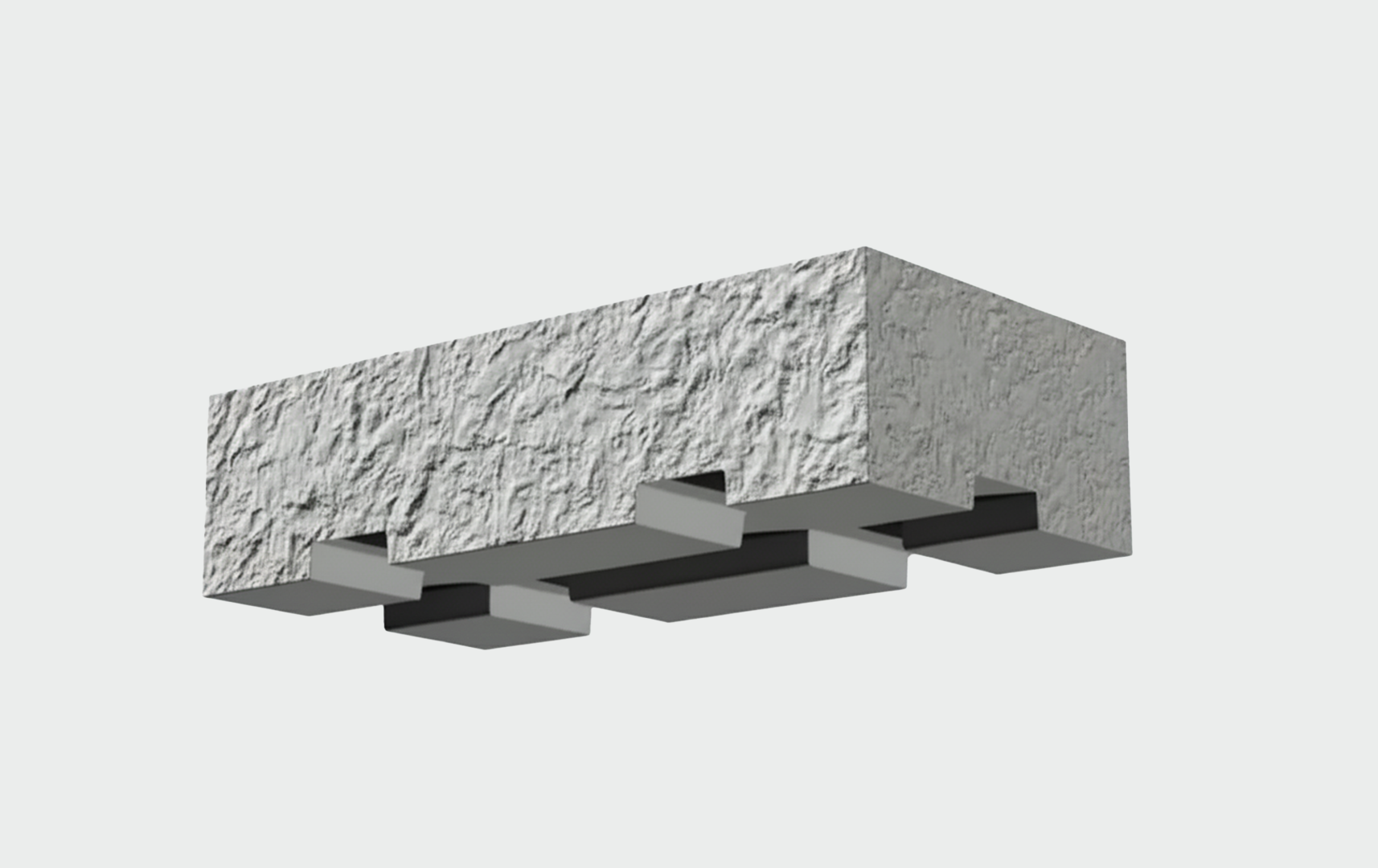

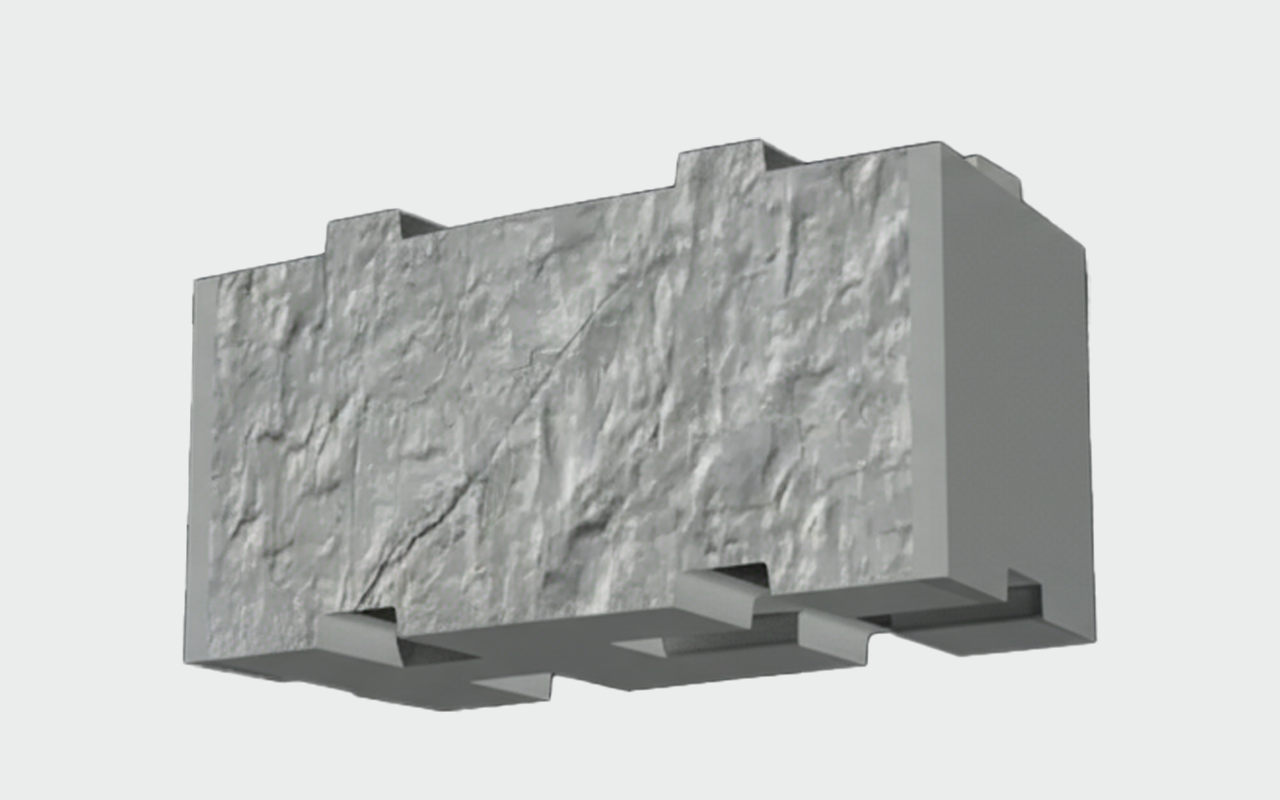

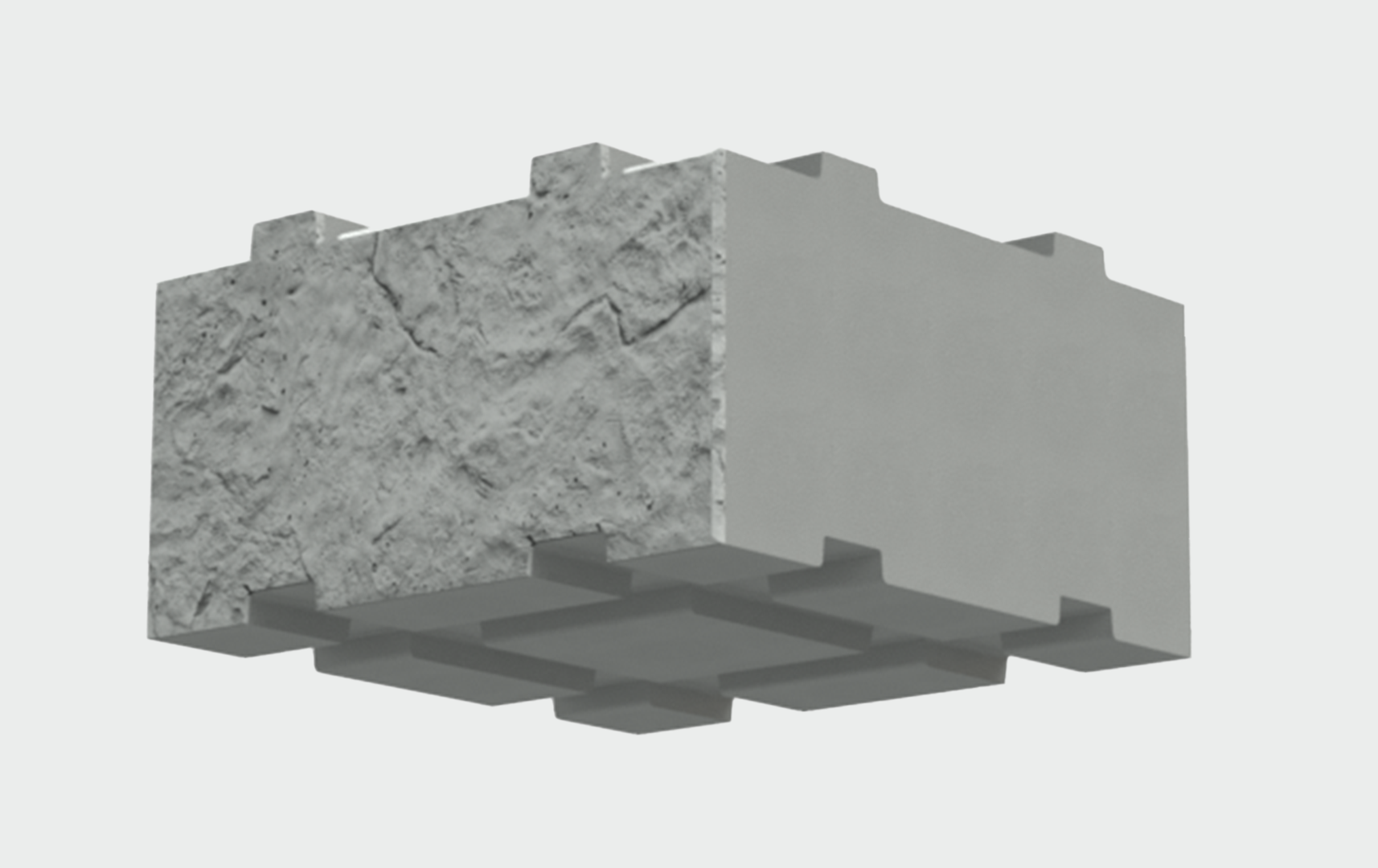

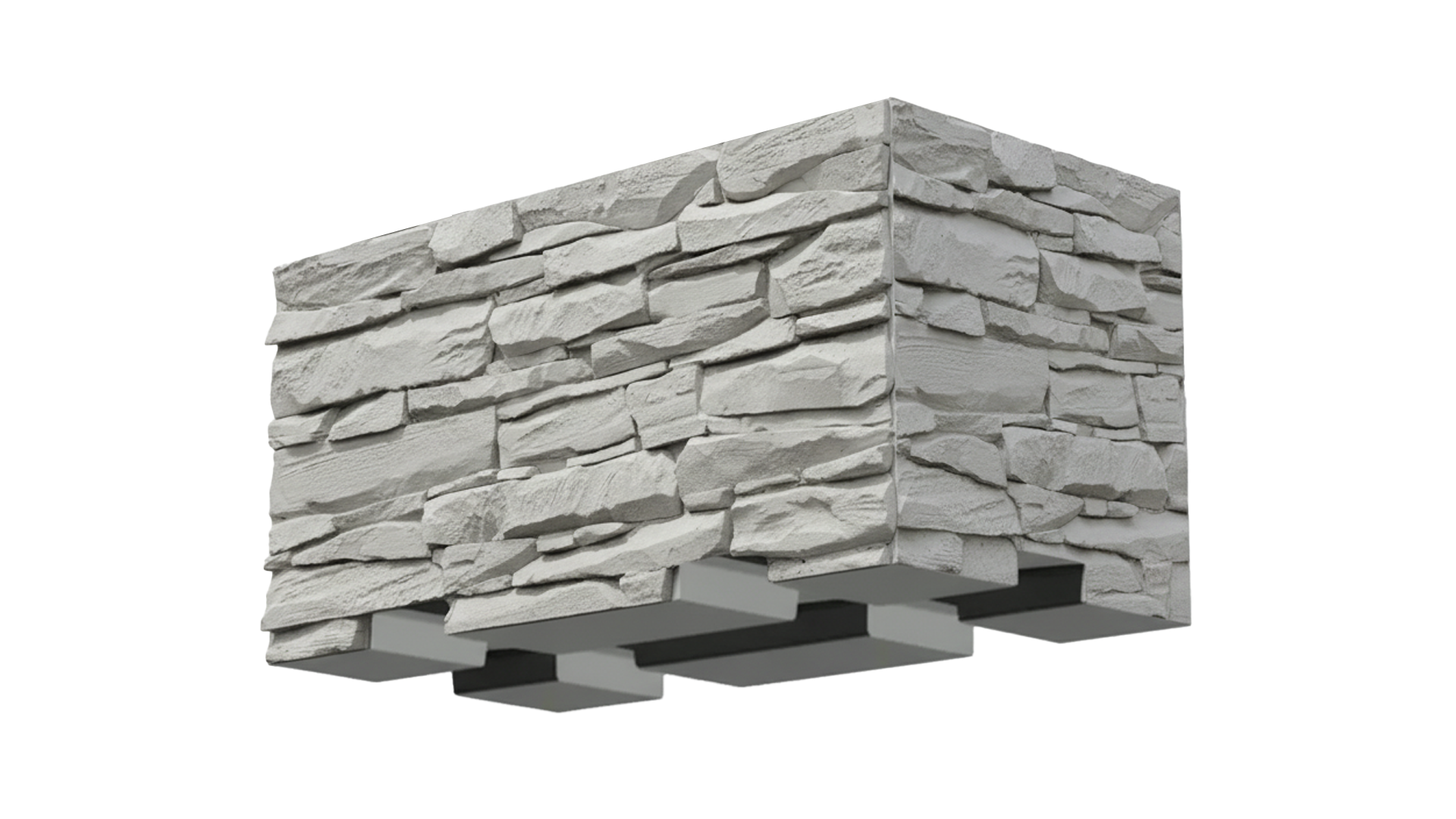

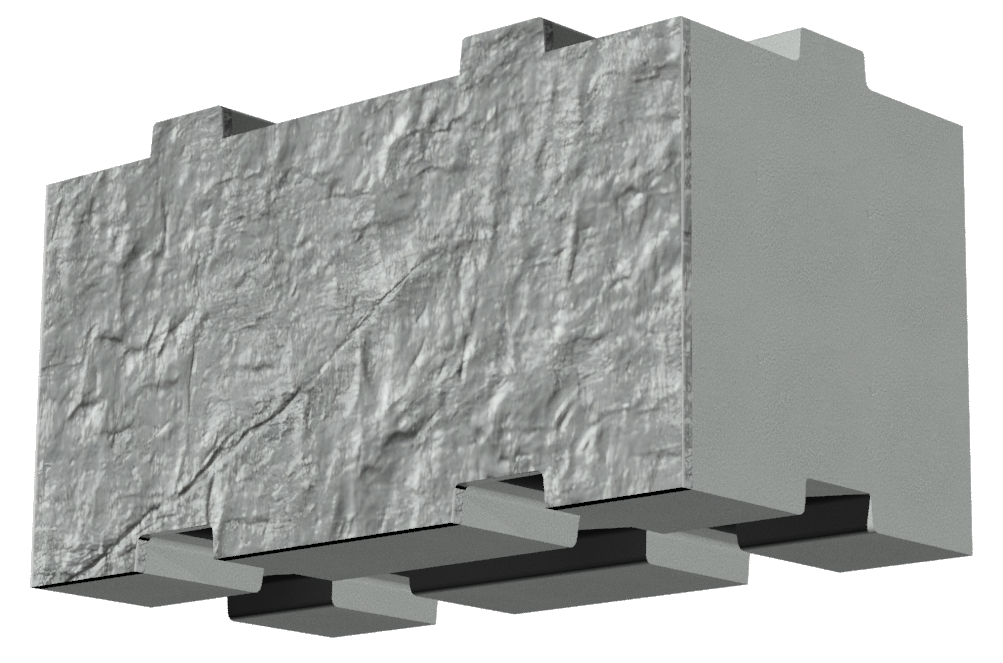

The system uses precision-cast, interlocking concrete blocks with integrated connection features that ensure rapid, accurate assembly and exceptional stability. Interbloc+ provides flexible design options - from pure gravity walls to reinforced and mechanically stabilised configurations - allowing it to adapt to a wide range of site conditions and aesthetic requirements.

With its modular design, streamlined installation, and proven New Zealand engineering, Interbloc+ eliminates much of the manual labour and complexity associated with traditional retaining wall systems - offering a faster, safer, and more sustainable way to build.

Benefits of Interbloc+

Interbloc+ is best used for

Product Information

PRODUCTION & QUALITY ASSURANCE

Block Specifications

Block Specifications

Specifications Guide

Gravity Wall Charts

MSE Specifications

Design Software

Interbloc+ Selection

Our expanding selection of premium textures offers both modern and natural finishes. Click any block to learn more and be redirected to our eCommerce store for small-volume purchase orders.

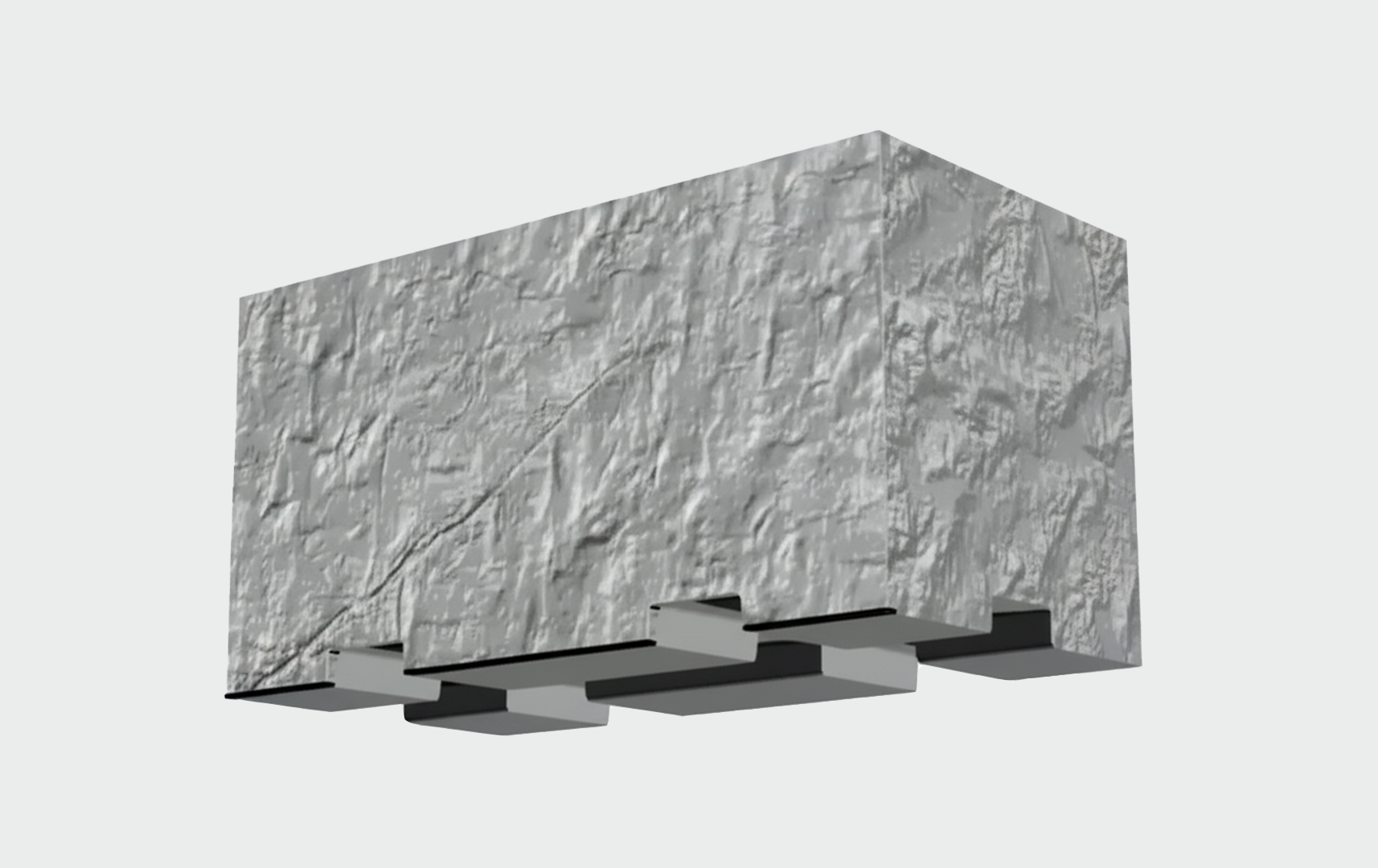

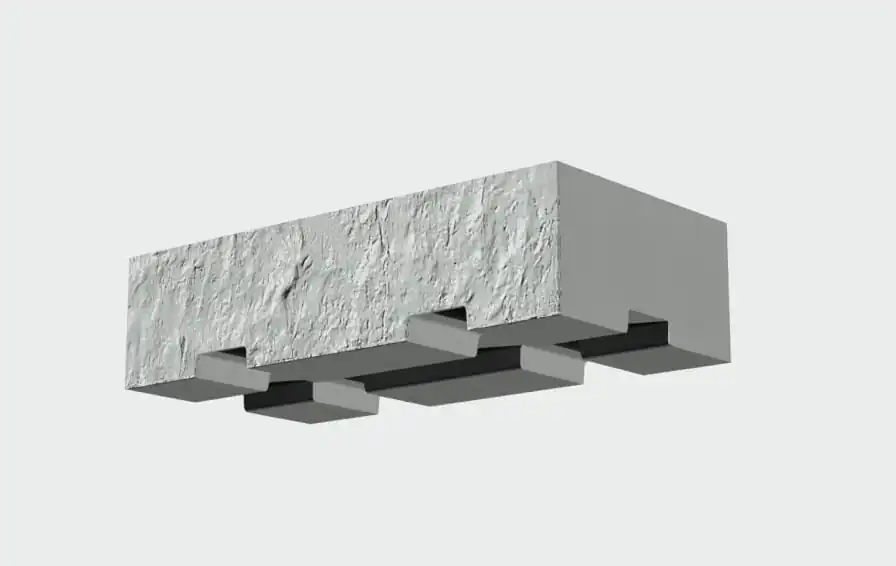

Croatia

Sleek and modern, the Croatia texture offers a smooth finish with durability, safety, and efficiency built into every Interbloc+ block.

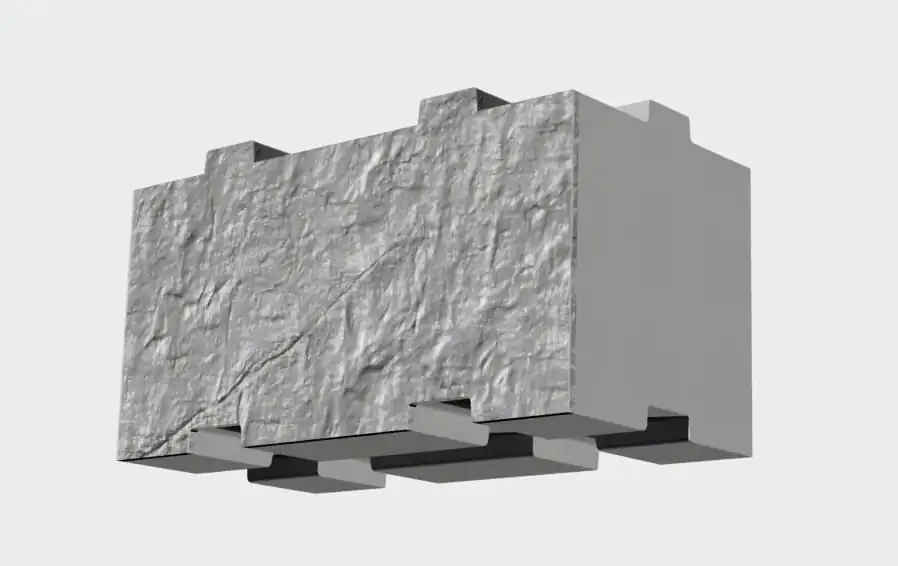

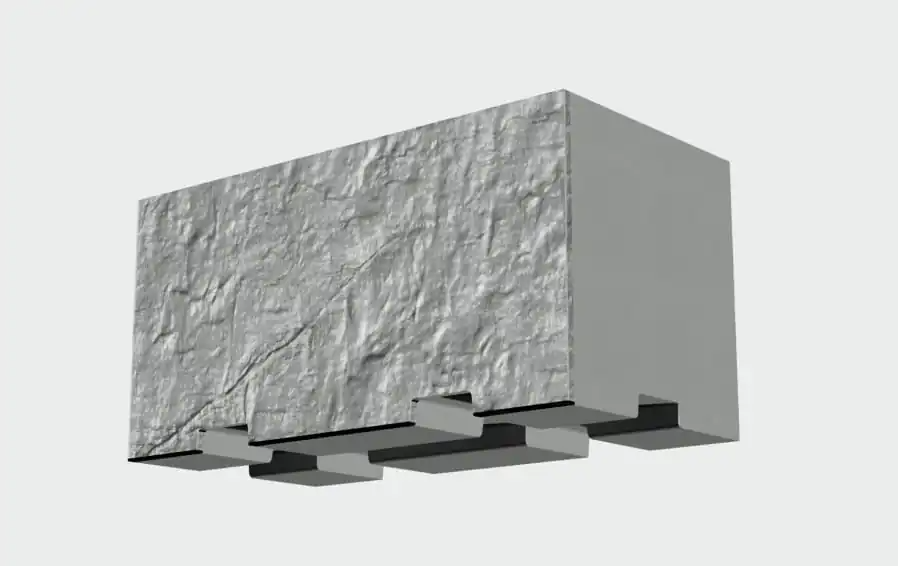

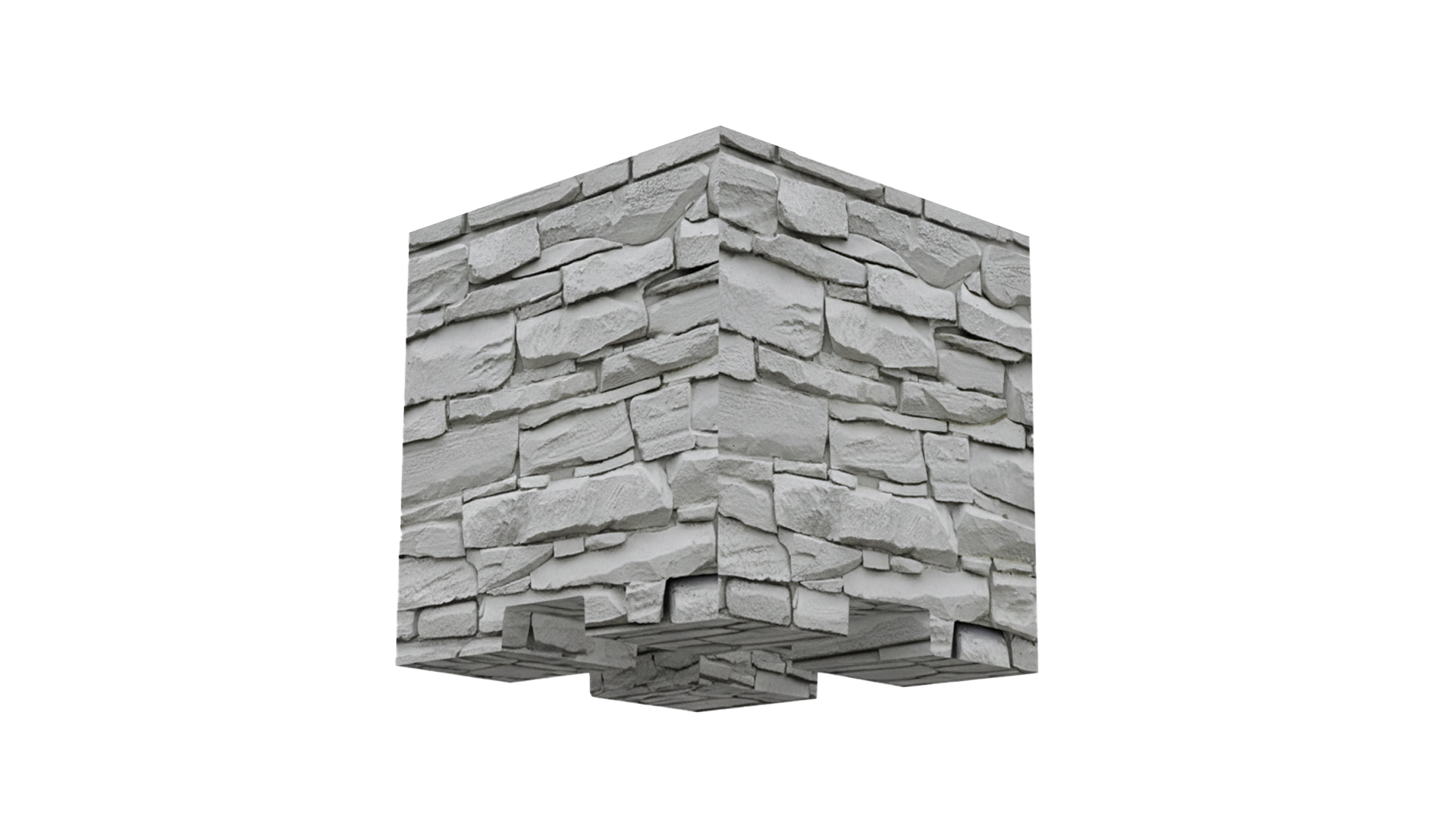

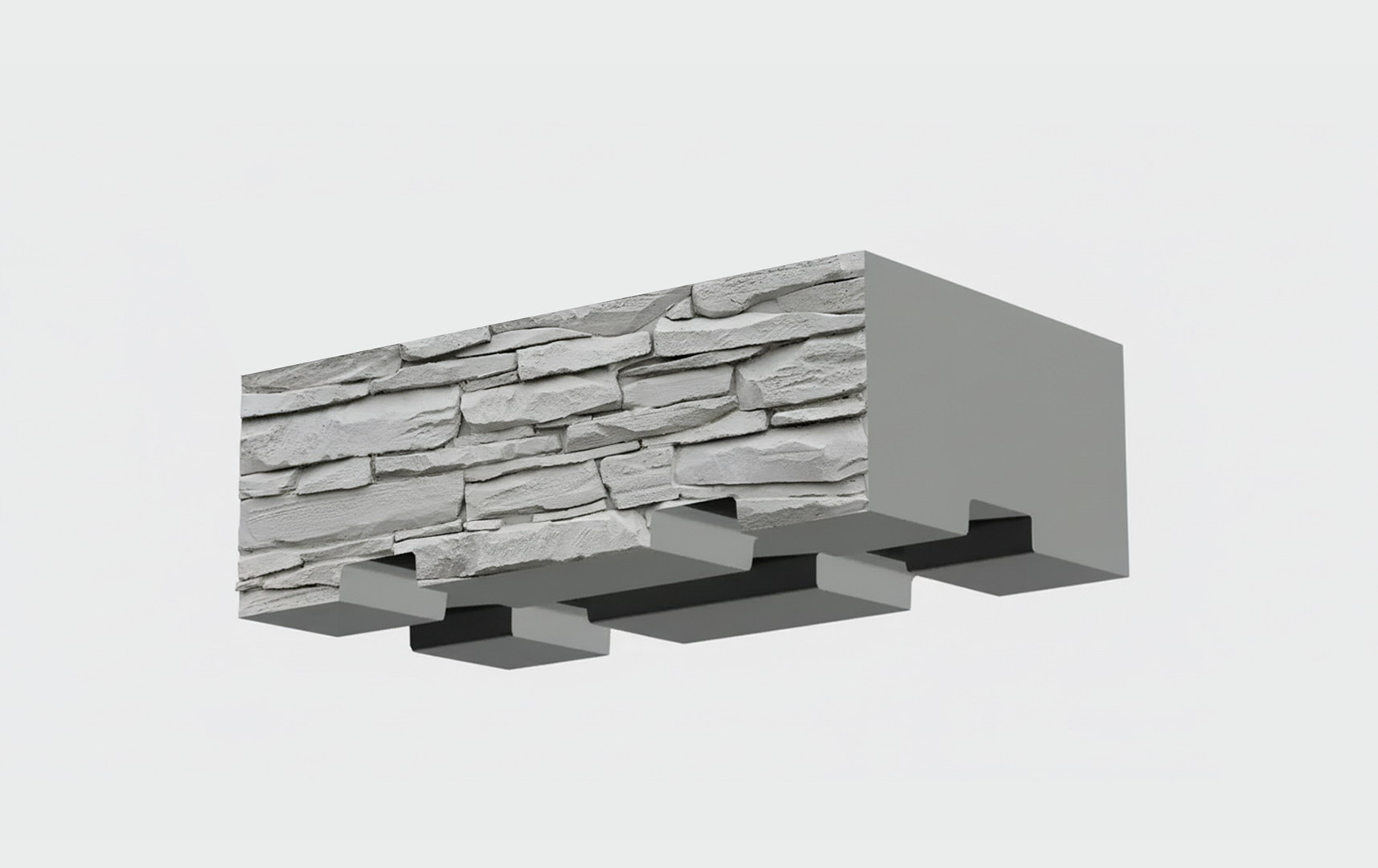

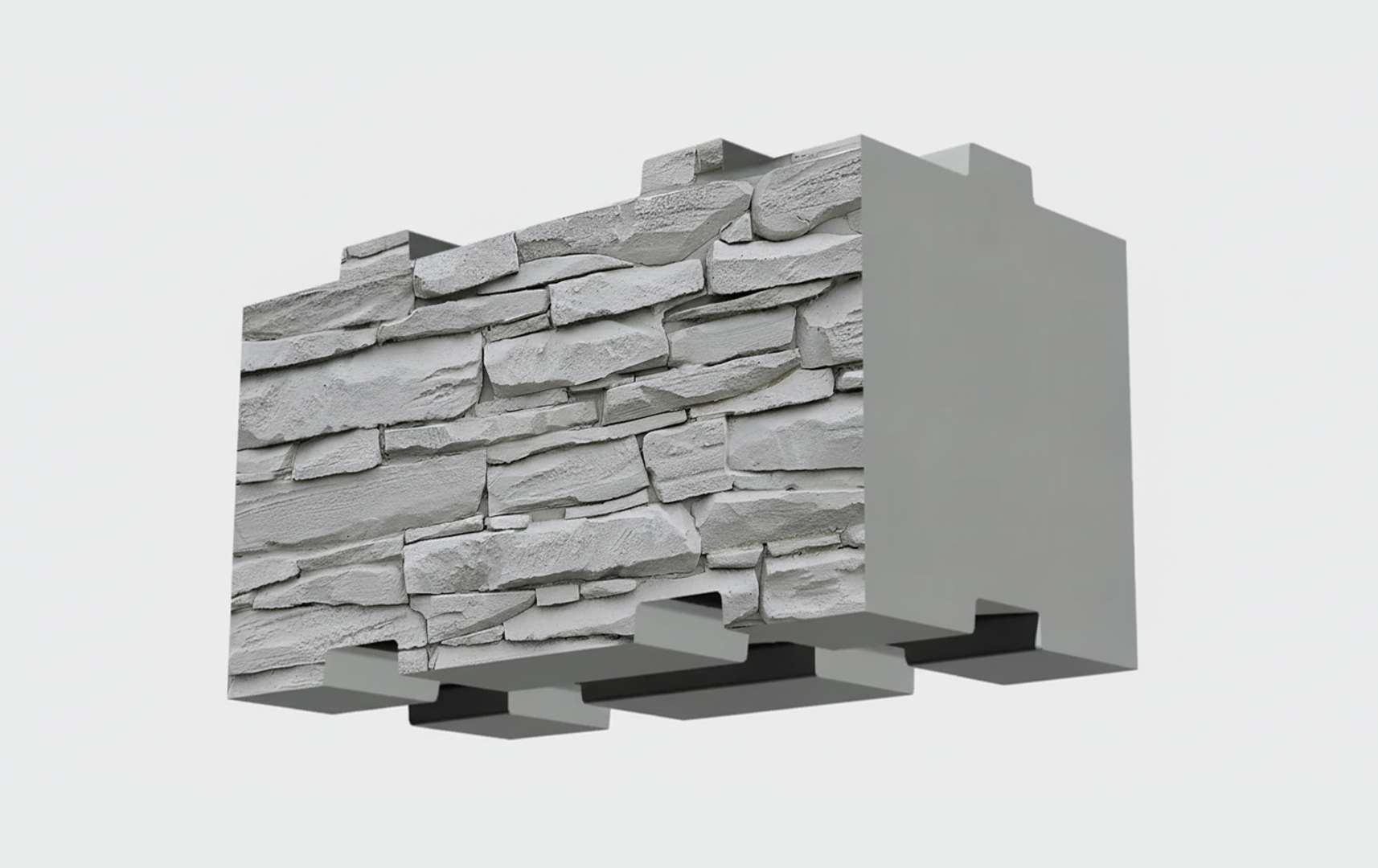

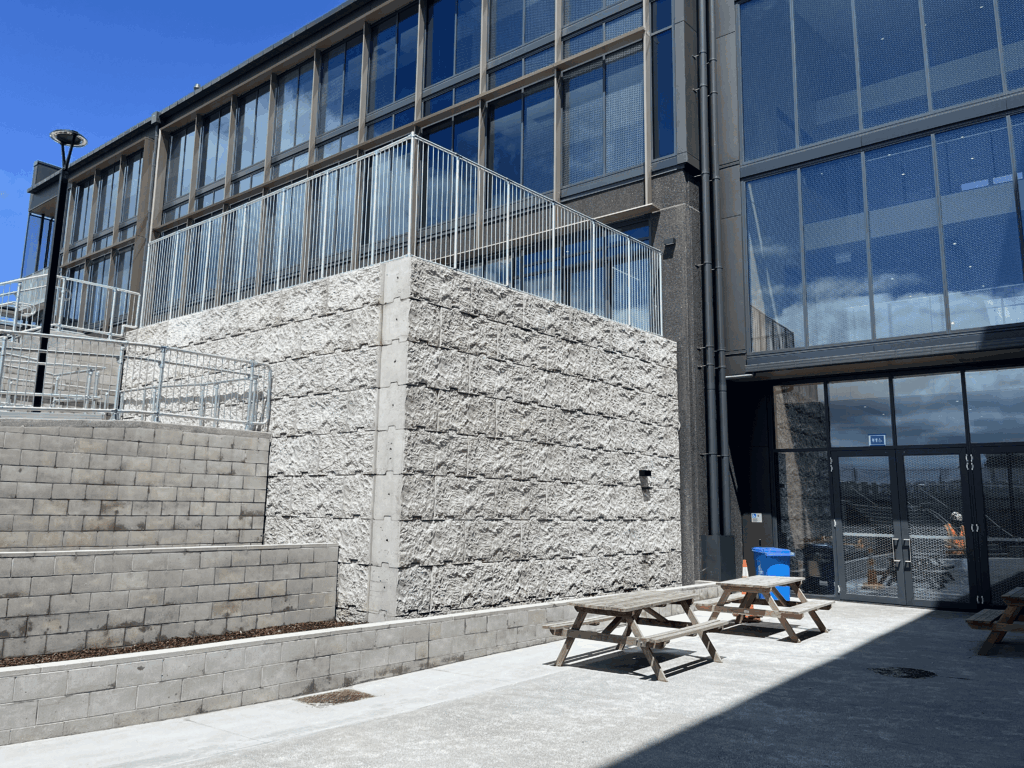

Schist

Rugged and natural, the Schist texture mirrors the look of layered stone. It delivers timeless character, strength, and quick installation within the engineered Interbloc+ system.

Envirocalc

EnviroCalc is a purpose-built software solution that ensures your retaining wall designs meet all NZBC requirements. Unlike generic engineering programs adapted for New Zealand, EnviroCalc is designed specifically for Interbloc and Stonebloc, simplifying complex calculations and generating accurate, compliant reports.

Envirobuild

EnviroBuild is Envirocon's 3D design tool for quickly creating Interbloc and Stonebloc structures, complete with precise dimension control, terrain adjustment, real-time measurements, colour toggles, and automated block quantity lists. Designs can be shared for collaboration and submitted directly to our Sales team for quoting, streamlining the entire workflow from concept to cost.

INTEGRATING INTERBLOC+ INTO ROCSCIENCE RSWALL BLOCK LIBRARY

First download the CSV file. To install the library, please follow these steps:

In RSWall, go to the Wall tab.

Click the Define Wall Units button.

In the new window, click the pencil icon (Edit Manufacturer Library) in the top right.

In the next window, click the User Defined Manufacturers button.

Click the + Add Library button and select the attached CSV file to upload.